-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the mining industry, Gyratory Crusher Parts play a critical role in maintaining operational efficiency. According to a recent report by Research and Markets, the global market for these components is expected to grow significantly, driven by increased mining activities. The demand for durable and reliable parts is higher than ever.

Dr. Emily Carter, a renowned expert in mining machinery, noted, "Choosing the right Gyratory Crusher Parts can significantly enhance performance and reduce downtime." This statement highlights the importance of selecting quality components. When gaskets, liners, and other parts wear out, it can lead to costly interruptions.

However, sourcing high-quality Gyratory Crusher Parts isn't without challenges. There is a sea of options, and not all suppliers maintain the same standards. This can lead to subpar performance and unexpected failures. Mining professionals must remain vigilant. As they navigate this complex market, careful consideration of their choices will be crucial for future success.

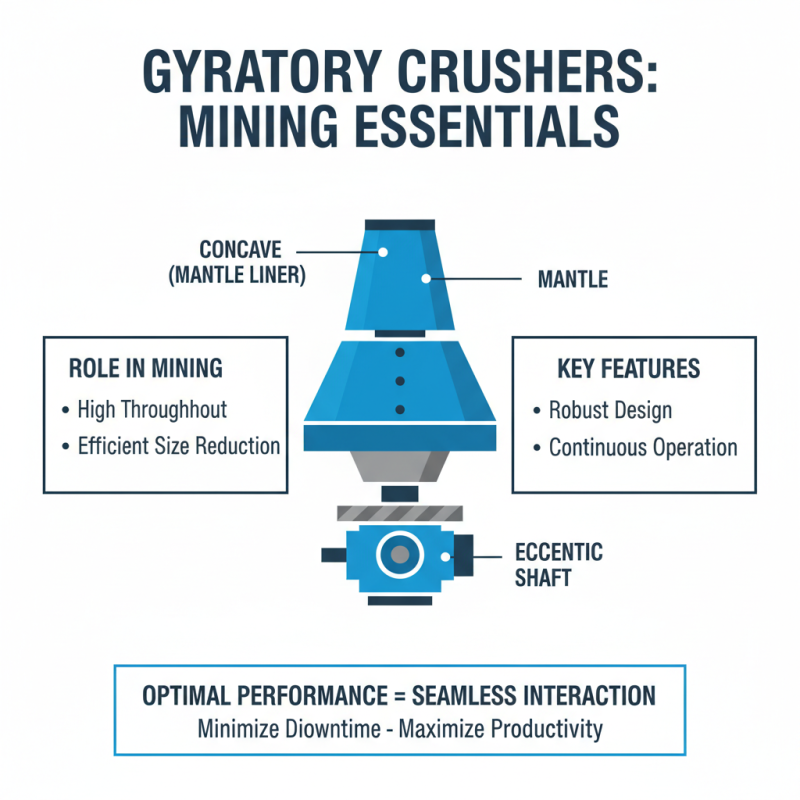

Gyratory crushers play a crucial role in the mining industry. Understanding their key components is essential for effective operation. The main parts include the mantle, concave liners, and the main shaft. Each component has a specific function that contributes to the overall efficiency of the machine.

The mantle, often made of high-carbon steel, is responsible for crushing the rock. It moves in a circular motion, exerting pressure on the material. Concave liners, situated opposite the mantle, trap and crush the rock as it enters the crushing chamber. Data shows that improper alignment of these components can lead to reduced efficiency and increased wear. A study suggests that poorly maintained parts can lead to up to 30% decrease in operational efficiency.

The main shaft is the backbone of the crusher. It transmits power from the drive assembly to the mantle. Issues with the main shaft can cause significant downtime. Many operations overlook routine checks on these parts, which can lead to failures. Reports indicate that unplanned maintenance can cost mining companies up to 5% of their annual revenue. Regular inspection and maintenance practices can mitigate these risks, ensuring a more reliable operation.

Gyratory crushers play a crucial role in mining operations. Their design allows for high throughput and efficient size reduction. Essential parts include the mantle, concave, and eccentric shaft. Each component must work together seamlessly for optimal performance. Failure of any part can result in costly downtime.

Research indicates that proper maintenance can enhance the lifespan of these components. According to industry reports, minor adjustments can lead to a 15% increase in efficiency. However, many operators overlook the importance of regular inspections. They often wait until a part fails before taking action. This reactive approach can be detrimental. It's vital to adopt preventive practices.

Moreover, understanding wear patterns on the mantle and concave is essential. These parts experience significant stress during operation. Operators should monitor them regularly to avoid unexpected failures. Some mines report that monitoring wear can cut operational costs by up to 20%. Ignoring these details can lead to reduced productivity and increased expenses. Regular maintenance checks and data analysis are key to improving operational efficiency.

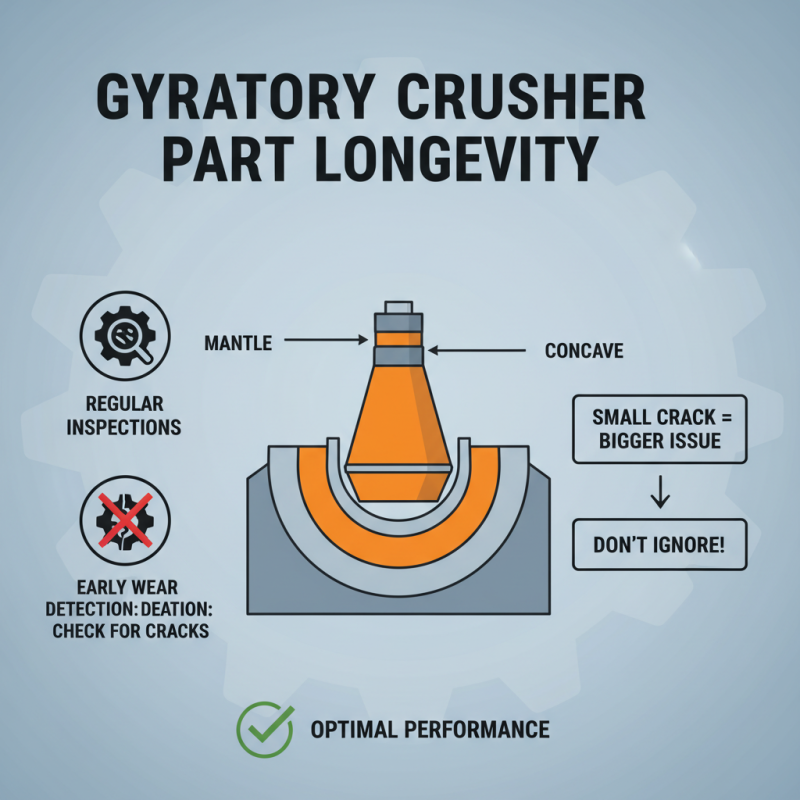

Maintaining the longevity of gyratory crusher parts is essential for optimal performance. Regular inspections can identify signs of wear early. Check for cracks or significant wear on mantles and concaves. A small crack can lead to larger issues, so don’t ignore them.

Proper lubrication is crucial. Ensure grease is applied consistently to bearings and other moving parts. Without adequate lubrication, friction increases, leading to faster wear. Monitor the lubrication levels and replace fluids in accordance with operational guidelines.

Operator training is also important. Ensure your team understands how to operate the equipment safely. Improper handling can accelerate component wear. Regular training sessions can help reinforce good practices. Keep an eye on operational metrics. High vibration levels can indicate a problem needing immediate attention. Don’t wait until it’s too late to address these issues.

When selecting replacement parts for gyratory crushers, professionals must focus on quality and compatibility. The right parts can significantly enhance crusher performance. Unmatched components may lead to unexpected downtime. Inspecting your current equipment can reveal wear patterns.

Choosing parts made from durable materials is essential. High-grade steel can withstand heavy workloads. However, some manufacturers might offer cheaper alternatives. These alternatives may not provide the same longevity. It's crucial to verify each part’s specifications.

It's common to overlook smaller components. These can affect the entire system's efficiency. Pay attention to bushings and seals. Neglecting them could lead to costly repairs later. Regular maintenance can help in identifying these issues early. Always keep a checklist of parts that require regular inspection and replacement. This practice helps maintain the crusher's overall health.

The future of gyratory crusher parts is closely tied to advancements in mining technology. As the industry evolves, materials used in crusher components will likely shift toward more durable and lightweight options. Innovative alloys can enhance the lifespan of these parts, reducing downtime and maintenance expenses. Effective implementation of these materials poses challenges. Many miners may need to adapt their operational procedures.

Automation is another trend to consider. Implementing smart technologies can optimize crusher performance and reduce human error. Real-time monitoring systems will allow for predictive maintenance. Miners could benefit from data analytics, but it requires a commitment to training and change. The integration of automation may feel overwhelming for some operators.

Sustainability is a pressing issue. Mining companies are under pressure to reduce their environmental impact. Gyratory crushers that consume less energy and produce less waste are essential. However, bridging the gap between innovation and sustainability remains complex. It's crucial for mining professionals to stay informed and be willing to experiment with new approaches. The path ahead is filled with potential and uncertainty.

This chart illustrates the projected market demand for various gyratory crusher parts in 2026. The data indicates that mantles and concaves will have the highest demand, reflecting their critical role in operational efficiency and maintenance in the mining industry.