-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

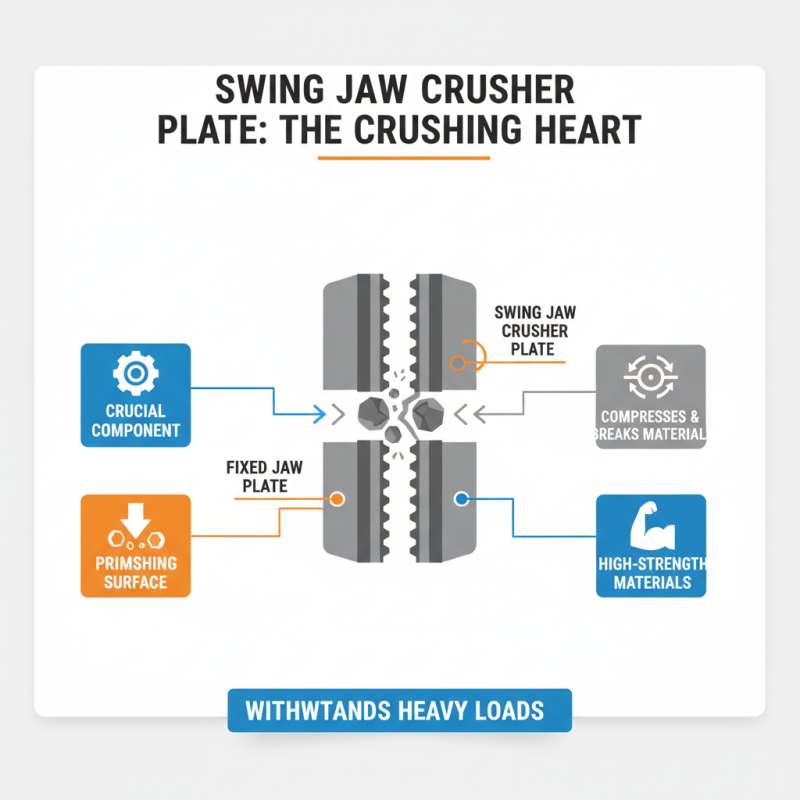

The Swing Jaw Crusher Plate is a crucial component in the operation of jaw crushers. Its primary function is to crush materials by applying pressure during the crushing cycle. The effectiveness of this plate directly impacts the overall performance of the crusher. A well-designed swing jaw plate can significantly increase efficiency. It can handle various materials, from hard rocks to softer aggregates.

Over time, wear and tear can compromise the swing jaw crusher plate's strength. This leads to decreased productivity and higher operational costs. Regular inspection and maintenance are vital. If the plate is not replaced timely, it can lead to equipment failure. This not only affects the machinery but also the flow of work.

In many cases, operators might overlook the importance of this part. Focusing solely on the more visible components can be tempting. However, understanding the impact of the swing jaw crusher plate is essential. It plays a pivotal role in ensuring the effective functioning of the entire system. Failure to recognize its importance can result in significant setbacks. This raises a challenge for those in the industry.

A swing jaw crusher plate is a crucial component in the operation of jaw crushers. It functions as the primary surface that crushes the material fed into the machine. As the swing jaw moves, it creates a space that compresses and breaks down the materials. This plate is often constructed from high-strength materials to withstand heavy loads.

The importance of the swing jaw plate cannot be understated. It directly impacts the efficiency of the crushing process. A well-designed plate can lead to better material processing and reduced operational costs. However, wear and tear can diminish its effectiveness. Regular inspections are necessary to identify signs of wear. Ignoring this can lead to operational issues.

The swing jaw plate must be properly maintained. It should be aligned and fitted correctly to avoid unnecessary strain on the crusher. Improper fitting may cause uneven wear, leading to inefficiencies. It’s essential for operators to keep track of the plate's condition. When it shows significant wear, it’s often too late to prevent problems. Thus, proactive measures are vital for optimal performance.

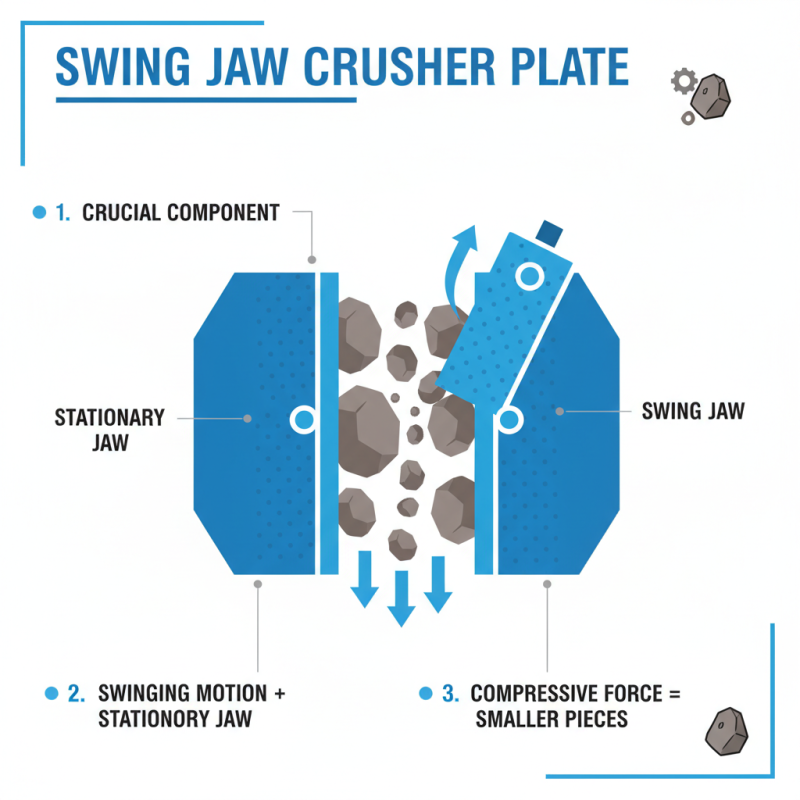

The swing jaw crusher plate is a crucial component in the crushing process. It plays a vital role in breaking down materials effectively. Its design allows for a swinging motion that works with the stationary jaw. This motion creates a compressive force to crush materials into smaller pieces.

Key components include the swing jaw, which is often made from high-strength steel. This ensures durability and resistance to wear. The jaw plate itself must have a perfect fit to the swing jaw. Any misalignment can lead to inefficient crushing and increased wear. A well-fitted plate enhances the overall performance of the crusher.

Tips for maintenance include regular inspections of the swing jaw and jaw plate. Look for signs of wear and tear. Addressing these issues early can prevent major breakdowns. Another tip is to ensure the crushing angle is optimized. A poor angle can decrease efficiency. Being attentive to these details can improve the longevity of the equipment.

Remember to keep your workspace clean. A cluttered environment can lead to accidents and machinery damage. Frequent checks on lubrication levels are also essential for smooth operation. By staying proactive, you can avoid costly repairs.

The swing jaw plate is a critical component of the jaw crusher. Its primary role is to facilitate the crushing process. As the swing jaw moves back and forth, it compresses material between itself and a fixed jaw. This motion creates powerful forces that break down large rocks into smaller particles. The effectiveness of the swing jaw directly impacts the overall performance of the crusher.

In crushing processes, the swing jaw's design is essential for maintaining efficiency. A well-engineered swing jaw ensures better material handling. However, wear and tear can lead to inefficiencies. Operators must regularly check for signs of damage or misalignment. This oversight can result in unnecessary downtime and higher operational costs. Balancing performance with maintenance is a constant challenge.

Monitoring the swing jaw's functionality also reveals how important it is to iron out flaws. Each adjustment can significantly influence the crushing effectiveness. Optimizing design elements can lead to smoother operations. However, overcomplicating the mechanism may hinder simple maintenance and daily checks. Therefore, finding the right balance is crucial for any operation.

Material selection for swing jaw plates is critical in the performance of a jaw crusher. The choice of material affects durability and efficiency. Common materials include manganese steel and various alloys. Manganese steel is favored for its high impact strength and resistance to abrasion. However, it can be quite expensive and requires careful handling during manufacturing.

While hardness and toughness are key attributes, other factors are also important. For example, weight plays a role in the dynamics of the crusher. A heavier jaw plate can provide stability but may reduce speed. Balancing these variables can be challenging. Many manufacturers still struggle with finding the right compromise.

In some cases, even the most durable materials can wear down faster than expected. Unexpected wear patterns can arise from inconsistent feeding or improper installation. Such issues highlight the importance of ongoing monitoring and maintenance. Selecting the right material isn’t just a one-time decision; it requires understanding the operational environment and potential challenges.

Maintenance of swing jaw plates is crucial for optimal operation. Regular inspection is key to identifying wear and potential failures. Operators should look for cracks, warping, or excessive wear patterns. Ignoring these can lead to costly downtime.

Proper lubrication is essential. Applying the right grease reduces friction and wear on moving parts. However, over-lubrication can lead to dirt buildup. Keeping the area clean is also important to prevent contaminants from interfering with the mechanism.

Periodic tightening of bolts is necessary to ensure the jaw plate remains securely in place. Loose bolts can cause misalignment, leading to uneven wear. Operators often overlook this simple task, yet it can significantly extend the plate’s lifespan. The need for consistent maintenance cannot be overstated. Small oversights can lead to major expenses.

| Maintenance Practice | Frequency | Potential Lifespan Increase | Notes |

|---|---|---|---|

| Regular Lubrication | Daily | 20-30% | Ensures smooth operation and reduces friction wear. |

| Daily Inspections | Daily | 15-25% | Identifies wear and potential issues early. |

| Component Alignment | Monthly | 10-20% | Prevents uneven wear on the swing jaw plate. |

| Bolt Tightening | Bi-weekly | 5-15% | Ensures the stability of the swing jaw plate. |

| Wear Monitoring | Quarterly | 10-15% | Tracks the plate’s condition and predicts replacement needs. |