-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the rapidly evolving landscape of the mining and construction industries, understanding the "Jaw Crusher Working" principles has become paramount for achieving top performance in 2025. Recent studies indicate that the global market for jaw crushers is expected to reach $2.5 billion by 2025, driven by the surging demand for minerals and aggregates. According to a report by Industry Insights, the efficiency and reliability of jaw crushers play a crucial role in maximizing productivity and minimizing operational costs, making the comprehension of their working principles even more essential.

Leading industry expert Dr. Sarah Mitchell emphasizes, "A thorough understanding of jaw crusher mechanics not only enhances operational efficiency but also prolongs the lifespan of the equipment." Her insights underline the significance of education and training in this domain, as companies seek to optimize their operations and maintain competitive advantages. As we delve into the intricate workings of jaw crushers, it becomes clear that mastering these principles is key for operators and engineers aiming for excellence in performance and innovation in the sector.

The jaw crusher is a pivotal piece of equipment in the mining and construction industries, known for its robust and effective crushing capabilities. To understand its performance, it is essential to dissect its basic structure and components. Primarily, a jaw crusher consists of two main parts: the fixed jaw and the movable jaw. The fixed jaw remains stationary, allowing the material to be crushed between it and the moving jaw as it performs a back-and-forth motion, facilitating the reduction of the particle size.

The efficiency of a jaw crusher is greatly influenced by its design variables and wearable components. A report from the Mining Equipment Association revealed that jaw crushers account for nearly 30% of total equipment sales in the mining sector, underscoring their critical role in material processing. Essential components include the jaw plates, which are typically constructed from high manganese steel for enhanced durability, and the toggle plate, which helps in adjusting the close side setting and affects the overall crushing force delivered. Understanding these elements is vital, as they directly influence the crusher's performance, throughput, and maintenance cycle.

Moreover, regular monitoring of these components can prevent unexpected downtimes, which are reported to reduce operational efficiency by up to 25%. By focusing on the fundamental structure and the roles of various components, operators can ensure optimal performance and longevity of their jaw crushing systems in the challenging landscape of mining and construction.

The jaw crusher is a critical machine in various industrial applications, primarily for its ability to break down materials through three fundamental mechanisms: crushing, compression, and impact forces. According to a recent industry report, the global jaw crusher market size is projected to reach USD 1.8 billion by 2025, growing at a CAGR of 5.2% from 2020, underscoring the machine's significance in the mining and construction sectors.

Crushing is the primary function of a jaw crusher, where the material is subjected to powerful yet controlled pressures. The design allows for a narrow opening at the top, which widens towards the bottom, effectively reducing material size as it progresses through the machine. This process is enhanced through compression forces, whereby the two jaw plates come together, thereby squeezing the material until it fractures. The energy efficiency of this compression method is evident, as it minimizes wear while maintaining high throughput levels, aligning with R&D findings that emphasize maximizing resource utilization.

Impact forces also play a crucial role in the performance of jaw crushers. As the material is crushed, it often encounters rebound effects from the other jaw plate, which can create additional fragmentation. This multi-faceted approach ensures a rapid and effective size reduction, making jaw crushers indispensable in applications requiring large volumes of crushed material. Research indicates that advancements in crusher design, focusing on optimizing these fundamental working principles, will not only enhance performance but also reduce operational costs in the long term.

The performance and efficiency of jaw crushers are significantly influenced by the properties of the materials being processed. Hardness, elasticity, and abrasiveness are critical factors that can affect the efficiency of the crushing process. For instance, harder materials require more energy and time to crush, which can lead to increased wear on the crusher's components and decreased overall productivity. In contrast, softer materials may be crushed more efficiently, helping to optimize the operation of the crusher and prolong its lifespan.

Tips: When selecting materials for processing, consider conducting a preliminary analysis of their properties. This will help you gauge the potential impact on the crusher's performance and make adjustments to your operation accordingly.

Additionally, the size and moisture content of the material can also play a pivotal role. Larger particles may obstruct movement and cause blockages, leading to operational inefficiencies. Excess moisture can lead to clumping, making it difficult for the crusher to produce a uniform product. By monitoring these characteristics and adjusting the feed as needed, operators can achieve better control over the crushing process and enhance product quality.

Tips: Implement a regular maintenance schedule to keep your crushing equipment in optimal condition, which will also help manage the negative impacts that material properties can have on performance.

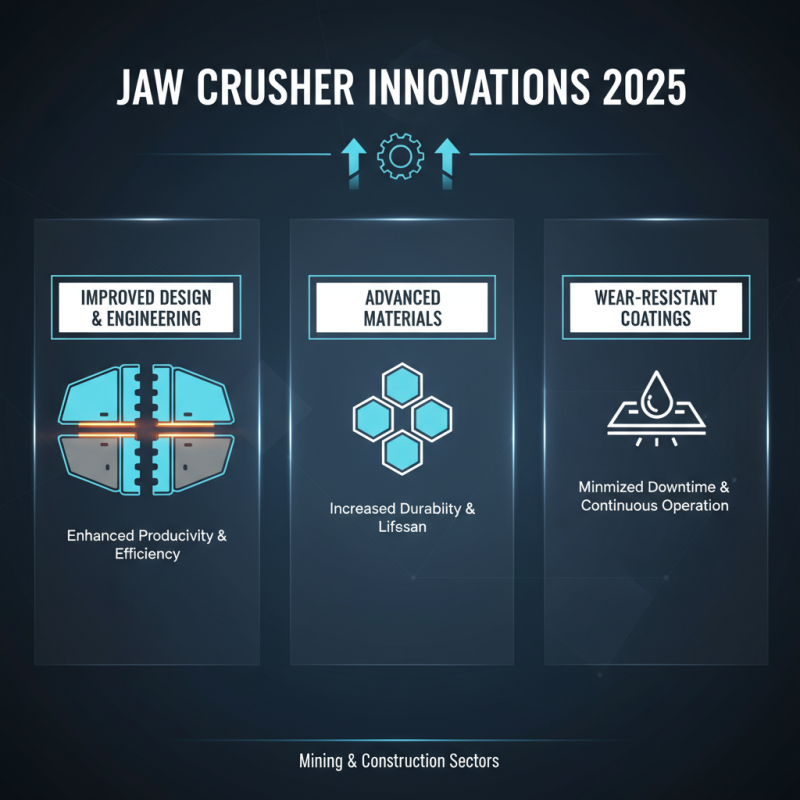

The evolution of jaw crusher technology is critical in enhancing productivity and efficiency within the mining and construction sectors. In 2025, innovations are poised to transform how these machines operate, focusing on improved design principles and smarter engineering solutions. Advanced materials are being utilized to increase the durability and lifespan of jaw crushers, allowing them to withstand more strenuous conditions while maintaining optimal performance levels. Additionally, innovations in wear-resistant coatings are set to minimize maintenance downtime, enabling continuous operation in high-demand environments.

Furthermore, the integration of smart technology will revolutionize the way jaw crushers function. Sensors and automation systems are being developed to monitor performance in real time, providing operators with immediate feedback and predictive maintenance alerts. This data-driven approach not only enhances operational efficiency but also contributes to safer working conditions by minimizing human error. As manufacturers prioritize these technological advancements, the focus remains on maximizing productivity while reducing operational costs, setting the stage for jaw crushers to achieve unprecedented heights in 2025 and beyond.

To achieve optimal performance and longevity from jaw crushers, understanding and implementing critical maintenance practices is paramount. Industry studies indicate that regular maintenance can extend the lifespan of jaw crushers by up to 30%. Key practices include routine inspections to detect wear and tear on critical components such as the toggle plate and bearings, which are pivotal in maintaining the crusher's efficiency. According to the National Stone, Sand & Gravel Association, improper maintenance can lead to a 15% reduction in output, emphasizing the importance of these checks in maximizing operational capacity.

Furthermore, adhering to proper lubrication schedules is crucial for the smooth operation of the jaw crusher. The American Institute of Mining, Metallurgical, and Petroleum Engineers reports that proper lubrication can reduce friction by up to 70%, significantly decreasing the risk of overheating. Operators should ensure that grease levels are maintained as per manufacturer specifications, focusing on areas like the toggle seat and swing jaw. Regular replacement of wear parts is also critical; delaying replacements can double operational costs due to increased energy consumption and downtime. By adhering to these maintenance practices, operators can enhance not just the efficiency of their equipment but also its overall reliability in processing materials effectively.