-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Jaw Crusher Wear Parts are critical components in mining and construction. These parts endure significant stress during operation. They include jaw plates, cheek plates, and other essential elements. Properly functioning wear parts ensure efficiency and reduce downtime.

Over time, these parts wear down. This wear can lead to decreased performance and costly repairs. Understanding the importance of wear parts is vital for maintaining productivity. Regular inspections can help identify wear and tear before it becomes a major issue.

Failure to monitor Jaw Crusher Wear Parts can lead to catastrophic breakdowns. Inattention may cost companies time and money. Therefore, investing in quality wear parts is essential. It can enhance a jaw crusher's lifespan and reliability. Operators must be aware of this critical aspect of their machinery.

Jaw crusher wear parts are vital components in the operation of crushing machines. These parts include the jaw plates, cheek plates, and the toggle plate. They are designed to withstand high-impact forces and heavy loads. The wear parts interact closely with the material being crushed. Over time, they experience considerable degradation. This can affect the efficiency of the crusher.

Jaw plates, for instance, are exposed to constant wear as rocks and minerals pass through. They need to be replaced regularly to maintain optimal performance. Cheek plates safeguard the body of the jaw crusher. Yet, they too can suffer wear and tear, leading to operational issues. The toggle plate is crucial, as it provides tension and support for the operation. If it breaks or wears unevenly, it can cause significant problems.

Monitoring jaw crusher wear parts is essential. Some operators may overlook minor wear, which can escalate into major failures. Regular checks and replacements are needed to avoid downtime. Ignoring wear can lead to increased maintenance costs and reduced productivity. Being proactive is key. Keeping an eye on these parts ensures the crusher operates smoothly. It's a cycle of wear and attention that defines successful operations in crushing.

Jaw crushers rely heavily on wear parts for optimal performance. These components experience significant wear due to the constant crushing action, resulting in the need for regular replacements. The main types of wear parts include jaw plates, cheek plates, and toggle plates.

Jaw plates are the most crucial parts. They come into direct contact with the material being crushed. The material’s hardness and shape will influence how quickly these plates wear out. Cheek plates protect the structure of the jaw crusher, while toggle plates play a role in maintaining the tension of the jaw plates.

Tip: Regular inspections can identify wear early. This can prevent unexpected breakdowns and excessive repairs.

It's important to choose materials for wear parts wisely. Different materials offer various benefits. However, the right choice depends on the specific application and material being crushed. Over time, users may realize that their wear part selections don't match their operational needs.

Tip: Keep a record of wear rates. This helps improve future replacements. Analyzing performance can lead to better decisions next time.

| Wear Part | Material | Function | Importance |

|---|---|---|---|

| Jaw Plates | High Manganese Steel | Crushing of materials | Critical for efficient material reduction |

| Cheek Plates | Manganese Steel or Alloy Steel | Supports jaw plates and protects the frame | Prevents damage to the crusher body |

| Toggle Plate | Cast Iron or Steel | Transfers motion and absorbs shock | Ensures the jaw crusher operates smoothly |

| Wedge Plates | Steel | Adjusts the gap between jaw plates | Essential for maintaining product size |

| Bearing | Bronze or Steel | Supports moving parts and reduces friction | Crucial for durability and operational efficiency |

Wear parts in a jaw crusher play a crucial role in maintaining efficiency and performance. These components, including jaw plates and toggle plates, endure significant wear during operation. Regularly monitoring these parts can prevent unexpected failures. Worn out components can lead to reduced crushing capability and increased downtime.

Effective wear parts ensure optimal material handling. When they operate at peak conditions, the jaw crusher can deliver consistent output. A small crack or chip in a wear part can drastically affect the entire system. It's essential to identify these issues early. Addressing wear and tear promptly can save costs in the long run.

Neglecting wear part maintenance poses risks. A lack of proper inspection can lead to catastrophic failures. This reminds one that even minor flaws require attention. Operational efficiency hinges on the condition of these vital components. Keeping a watchful eye on wear parts is not just prudent; it’s essential for durability and productivity.

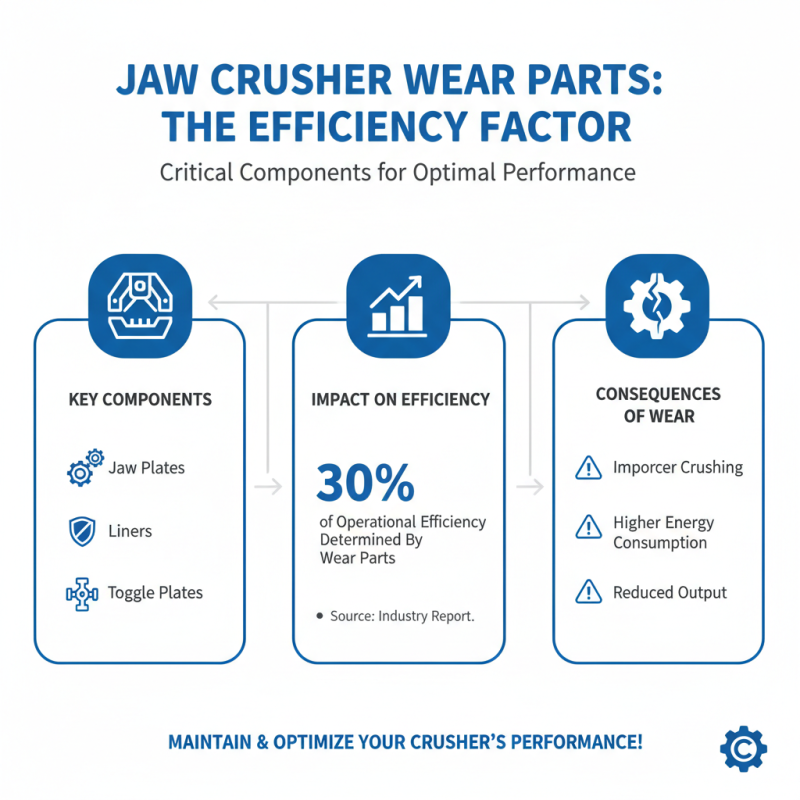

Maintaining and replacing jaw crusher wear parts is crucial for optimal performance. These components, such as jaw plates and liners, endure substantial wear. Industry reports indicate that improper maintenance can reduce productivity by up to 30%. Ensuring regular inspections can mitigate this issue. Operators should examine wear patterns closely. Minor defects can lead to significant breakdowns if not addressed.

Replacement of wear parts should be timely. Waiting too long can escalate repair costs and downtime. Many experts recommend replacing jaw plates when they have worn down to 20% of their original thickness. This proactive approach ensures the equipment runs efficiently. It's important to keep a record of wear part performance. Analyzing this data helps in scheduling future replacements.

Maintenance should include regular lubrication and cleaning. A clean machine operates better. A dirty jaw crusher may lead to overheating. Operators often overlook this simple step. However, addressing it can increase lifespan significantly. Neglecting these practices can result in costly repairs. In some cases, failure to maintain can void warranties or lead to safety hazards. Regular training for operators can help reinforce best practices in maintenance and parts replacement.

Wear parts are critical components in jaw crushers. These parts, which typically include jaw plates, liners, and toggle plates, experience significant wear over time. The effectiveness of a jaw crusher relies heavily on the condition of these components. According to a recent industry report, wear parts can determine a crusher's operational efficiency by as much as 30%. When wear parts deteriorate, they can lead to improper crushing, higher energy consumption, and reduced output.

The impact of worn-out parts on performance is often underestimated. For instance, if the jaw plates are not replaced in time, the entire process can slow down. Studies show that even minor wear can decrease throughput significantly. It can lead to increased energy usage and, ultimately, higher operational costs. Research indicates that regular monitoring and timely replacement of wear parts can improve the lifespan of a jaw crusher by 15% to 20%.

Many operators might overlook the importance of these components. This oversight can result in suboptimal crushing performance. The right balance in maintaining wear parts ensures consistent production rates and product quality. Without proper care, the issues surrounding wear can compound quickly. This highlights the need for a proactive maintenance approach to preserve operational integrity.