-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The world of Jaw Crusher Parts is complex yet vital for efficient mining operations. As the backbone of a jaw crusher, these parts play a crucial role in the machine's performance. According to a recent industry report by Global Market Insights, the jaw crusher market is expected to reach $4.5 billion by 2027, driven by increased mining activities and infrastructure development.

Expert Richard Smith, a renowned figure in crusher technology, states, "Understanding Jaw Crusher Parts is essential for optimizing machine longevity." His insight reflects the growing need for knowledge in maintaining and replacing these components. Each part, from the jaw plates to the toggle plates, contributes to the overall efficiency of the machine.

However, many operators overlook the importance of regular inspections. Neglecting minor wear can lead to significant downtime and costly repairs. Acknowledging these imperfections is the first step toward better maintenance practices. Ultimately, becoming acquainted with Jaw Crusher Parts can lead to improved productivity and reduced operational costs.

Jaw crushers are essential in the mining and construction industries. They operate by compressing materials to break them down. Understanding the functionality of their parts can enhance performance and efficiency. Key components like the jaw plates, toggle plate, and eccentric shaft play crucial roles in this process.

The jaw plates are the main point of contact with the material. They can wear out quickly, affecting output. Studies show that worn jaw plates decrease efficiency by up to 25%. Regular monitoring and timely replacement are vital. The toggle plate, meanwhile, acts as a safety mechanism and helps manage the crushing action. A failure in this part can lead to unexpected downtimes, which often go unnoticed until it's too late.

Being aware of these parts and their functionalities can save costs in the long run. Operators should keep an eye on these components. Many overlook the importance of lubrication in maintaining parts. Proper lubrication can improve the lifespan of jaw crushers significantly. It’s essential to reflect on maintenance strategies to avoid unnecessary breakdowns. Small neglects can lead to costly repairs and project delays.

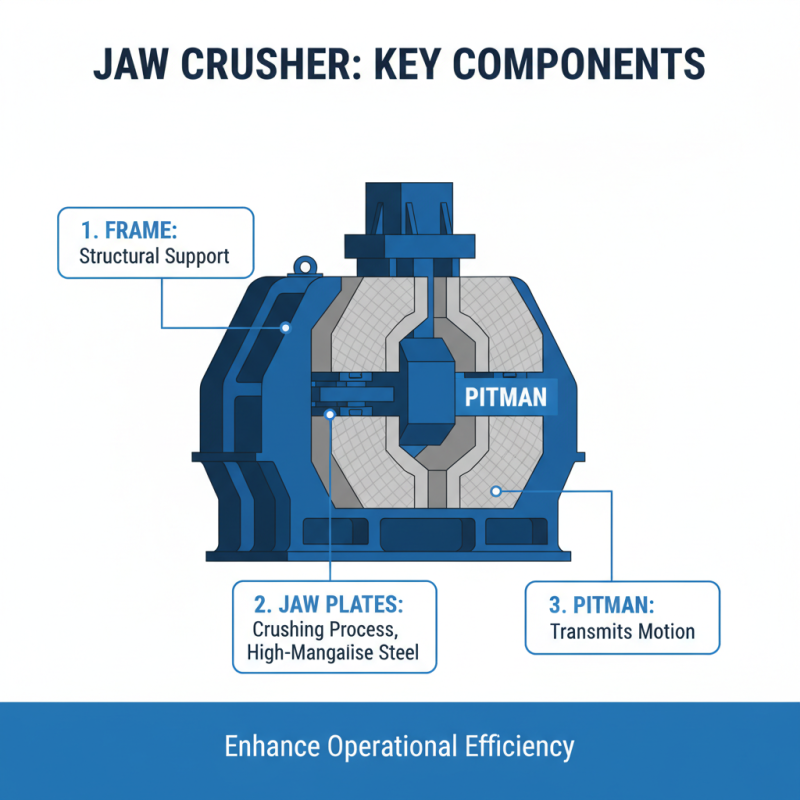

Jaw crushers are critical in the mining and construction industries. Understanding their key components can enhance operational efficiency. The main parts include the frame, jaw plates, and the pitman. The frame provides structural support. Jaw plates are essential for crushing processes, often made of high manganese steel for durability.

The pitman is the driving force behind the jaw’s motion. It connects to the flywheel and translates rotational motion into the linear action of the jaw. The importance of maintaining these parts cannot be overstated. Worn-out components can lead to reduced productivity. In fact, reports indicate that replacing worn jaw plates can improve throughput by up to 30%.

Tips: Regular inspection of jaw plates can prevent major breakdowns. Look for signs of wear, like fractures or excessive wear patterns. This way, you can save costs on repairs.

Also, ensure proper lubrication of the bearings. This helps avoid operational failures caused by overheating. Even a small oversight can lead to significant downtime. Keeping an eye on these details pays off in the long run.

Understanding the material composition and durability of jaw crusher parts is essential for efficient operation. Different materials are used to manufacture these parts, impacting longevity and performance. Common materials include

high-carbon steel,

manganese steel, and

alloyed iron. Each has its unique properties that affect wear resistance and toughness, making them suitable for specific applications.

When evaluating the durability of jaw crusher parts, consider factors such as

hardness and

impact resistance. Manganese steel, for instance, is renowned for its high impact strength. However, it can become brittle if not properly alloyed. This brittleness can lead to unexpected failures. Moreover, the environment in which crushers operate influences wear rates.

High temperatures and

abrasive materials can accelerate wear, demanding regular inspections and potential modifications.

Improper maintenance can exacerbate issues related to durability. Parts may degrade faster than anticipated if there's neglect. Regular monitoring of wear patterns is vital.

Operators should not overlook the importance of keeping accurate records of parts usage and maintenance schedules. This practice increases the lifespan of components and ensures reliable operation.

Maintaining jaw crusher parts is crucial for long-lasting performance. Regular inspections can prevent unexpected breakdowns. Check for wear and tear at least once a week. Look for cracks in the frame and monitor bearing wear. Minor issues often go unnoticed until it's too late. Developing a habit of consistent checks is essential.

Proper lubrication is key. Utilize the right type of lubricant for every moving part. Over-lubrication can lead to more problems than under-lubrication. Implement a schedule to maintain consistent lubrication levels. Cleaning the components also helps in reducing dust buildup. A clean machine tends to last longer, yet many neglect this simple task.

Operators should understand the crushing process. Misjudging material hardness can lead to excessive wear. Keep an eye on feed size and adjust accordingly. Sometimes, operators rush decisions, leading to unnecessary repairs. Reflecting on past mistakes can guide better choices in the future. Maintaining jaw crusher parts is an ongoing learning experience.

Jaw crushers are vital in many industries, but their components can face common issues. One frequent problem is wear and tear on the jaw plates. Over time, these plates lose their effectiveness. This deterioration can lead to reduced productivity. Inspecting jaw plates regularly is essential. If you notice significant wear, it's time for a change.

Another concern is misalignment of the crusher. Misalignment can cause uneven wear on components. It may also lead to unexpected downtime. Regularly check the alignment to prevent these headaches. Adjusting the machine properly can make a big difference.

Tips: Always keep an eye on the settings. Small adjustments can greatly improve performance. If you notice strange sounds, investigate immediately. These could be signs of deeper issues. Don’t ignore minor problems. They can turn into major repairs if left unattended. Regular maintenance pays off in the long run.