-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the competitive landscape of the mining and aggregate industry, the role of Cone Crusher Spare Parts cannot be overstated. According to a recent industry report by Grand View Research, the global cone crusher market is expected to reach USD 2.1 billion by 2025, underscoring the growing demand for efficient crushing equipment and the essential components that support optimal machinery performance. With downtime directly impacting profitability, ensuring the availability and quality of spare parts is crucial. Studies indicate that approximately 40% of total operating costs can be attributed to equipment maintenance, highlighting the importance of timely replacement and high-quality Cone Crusher Spare Parts in minimizing downtime and maximizing productivity. By leveraging industry best practices and understanding the significance of these components, operators can enhance the lifespan and efficiency of their cone crushers, ultimately leading to improved operational success.

In the mining and quarrying industries, the efficiency and reliability of operations heavily depend on the performance of equipment, particularly the cone crusher. Cone crushers are pivotal in processing a variety of materials, with the global cone crusher market projected to reach approximately $2.5 billion by 2027, growing at a CAGR of around 4.5% (Source: Industry Reports). This growth underscores the necessity for high-quality spare parts that can sustain optimal performance and reduce downtime.

The significance of cone crusher spare parts cannot be overstated. These components, such as liners, mantles, and bushings, play a critical role in the crushing process. Regular wear and tear can lead to operational inefficiencies and increased costs. According to a study by the Mining Industry Council, replacing worn-out parts can enhance operational efficiency by up to 30% and extend the lifespan of the equipment by several years. Investing in genuine spare parts not only ensures compatibility but also guarantees that the crushers can operate at peak productivity, thus maximizing profitability in mining and quarry operations.

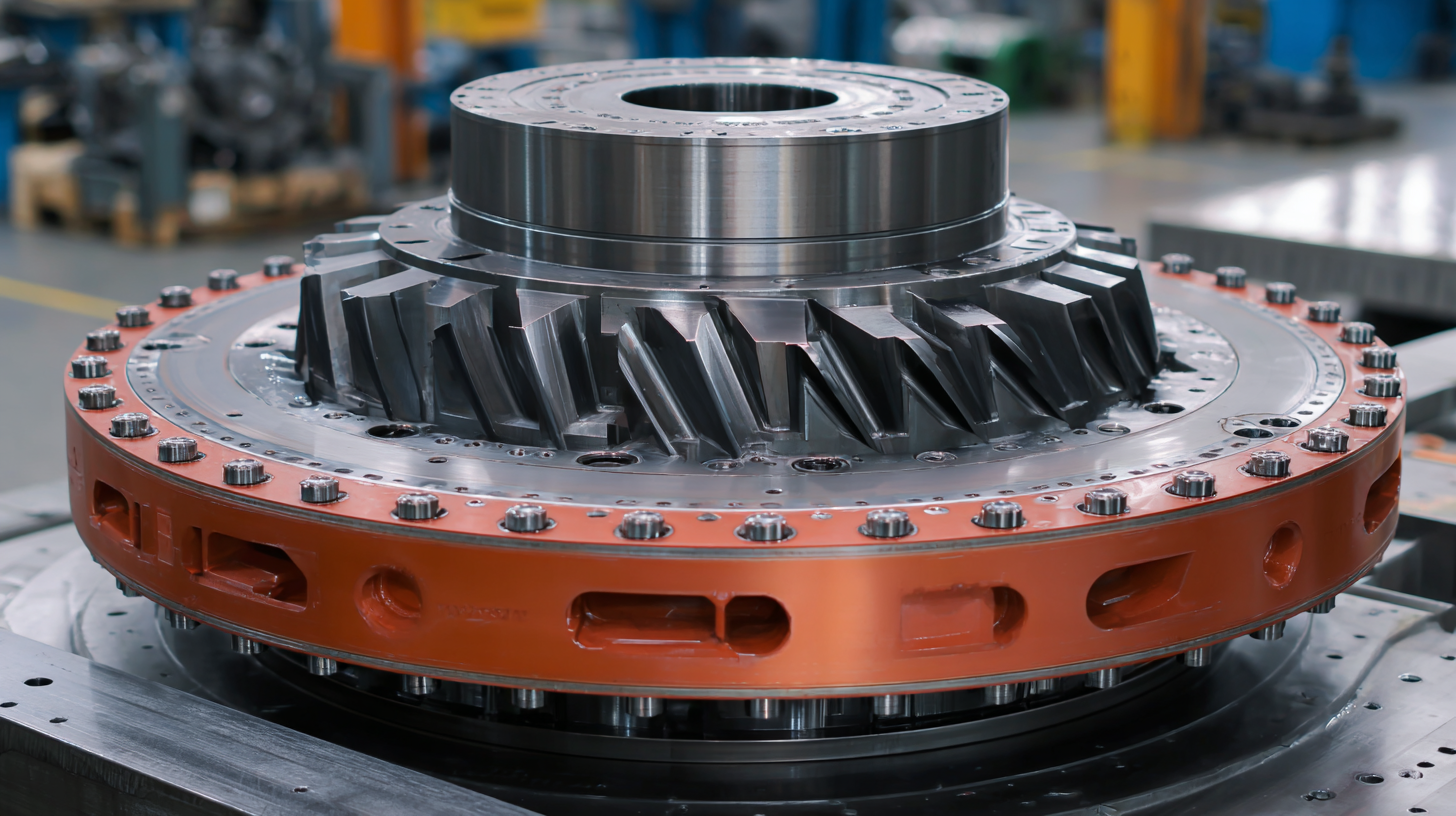

Cone crushers are critical in mining and aggregate processing, emphasizing the importance of understanding their spare parts. Key components, such as the mantle, bowl liner, and concave, play vital roles in the crusher’s performance. The mantle and bowl liner create the crushing chamber, where rocks are crushed through compression. The concave design influences the size and shape of the crushed material, impacting the quality of the end product.

Maintaining these components is essential for optimal performance. Regular inspections can help identify wear patterns early, allowing for timely replacements before performance drops. It’s also crucial to use high-quality spare parts to ensure compatibility and longevity.

Tip: When replacing the mantle or bowl liner, ensure that they are properly fitted and torqued to the manufacturer’s specifications. This enhances the crusher's efficiency and extends the lifespan of both the components and the entire machine. Additionally, regular lubrication maintenance can significantly reduce friction and wear, contributing to smoother operations.

Regular maintenance of cone crusher spare parts is essential for ensuring longevity and optimal performance. One of the best practices is to establish a routine inspection schedule. This involves checking the condition of critical components such as the mantle, bowl liner, and feed distributor. By regularly examining these parts for wear and damage, operators can identify issues before they escalate into major breakdowns, reducing downtime and repair costs.

Additionally, the lubrication system plays a crucial role in the performance of cone crushers. Using the right type and amount of lubricant helps to minimize friction and overheating, which can lead to premature wear of spare parts. It's important to adhere to the manufacturer's recommendations regarding lubrication intervals and to monitor oil levels regularly. Properly maintaining the lubrication system not only extends the life of the components but also boosts the overall efficiency of the cone crusher, maximizing productivity in the long run.

The efficiency and output of a cone crusher significantly depend on the quality of its spare parts. According to a recent industry analysis by the Mining Equipment Association, using high-quality replacement parts can enhance crushing performance by as much as 25%. This improvement is largely attributed to the precise engineering and durable materials used in top-tier spare parts. Inferior components can lead to increased downtime and wear, ultimately impacting productivity and operational costs.

When selecting spare parts, it’s crucial to consider factors such as material compatibility and manufacturer reputation. For example, studies have shown that using OEM (Original Equipment Manufacturer) parts minimizes the risk of premature failure and performs better under extreme conditions. Investing in quality spare parts not only boosts operational efficiency but also extends the lifespan of the equipment, translating to lower long-term maintenance costs.

Tips: Always consult with your equipment manufacturer or a trusted supplier when sourcing spare parts. Regularly inspect and replace worn-out components to maintain optimal performance. Remember, a small investment in quality parts today can lead to significant savings and efficiency gains in the long run.

When considering the maintenance and efficiency of cone crushers, the decision to invest in genuine spare parts becomes crucial from a cost-benefit perspective. While it may be tempting to opt for cheaper alternatives, these can lead to increased long-term expenses due to frequent breakdowns and the resultant downtime. Genuine spare parts are specifically designed to fit and perform optimally within the system, ensuring that the crusher operates at its full potential. This not only enhances productivity but also extends the lifespan of the equipment.

Furthermore, the initial investment in quality components can ultimately yield significant savings. Genuine parts tend to offer better performance and durability, reducing the need for frequent replacements and repairs. By minimizing unplanned maintenance and enhancing operational efficiency, companies can achieve a favorable return on investment. These advantages make a compelling case for prioritizing genuine cone crusher spare parts in the quest for reliability and performance in aggregate production and mining operations.

| Spare Part | Cost of Genuine Part ($) | Cost of Aftermarket Part ($) | Expected Lifespan (months) | Failure Rate (%) | Overall Savings Potential (%) |

|---|---|---|---|---|---|

| Mantles | 800 | 500 | 12 | 15 | 20 |

| Concaves | 900 | 600 | 10 | 10 | 25 |

| Bowl Liners | 700 | 400 | 14 | 12 | 22 |

| Main Shaft | 1500 | 900 | 20 | 5 | 30 |

| Adjustment Ring | 1300 | 800 | 16 | 8 | 28 |