-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

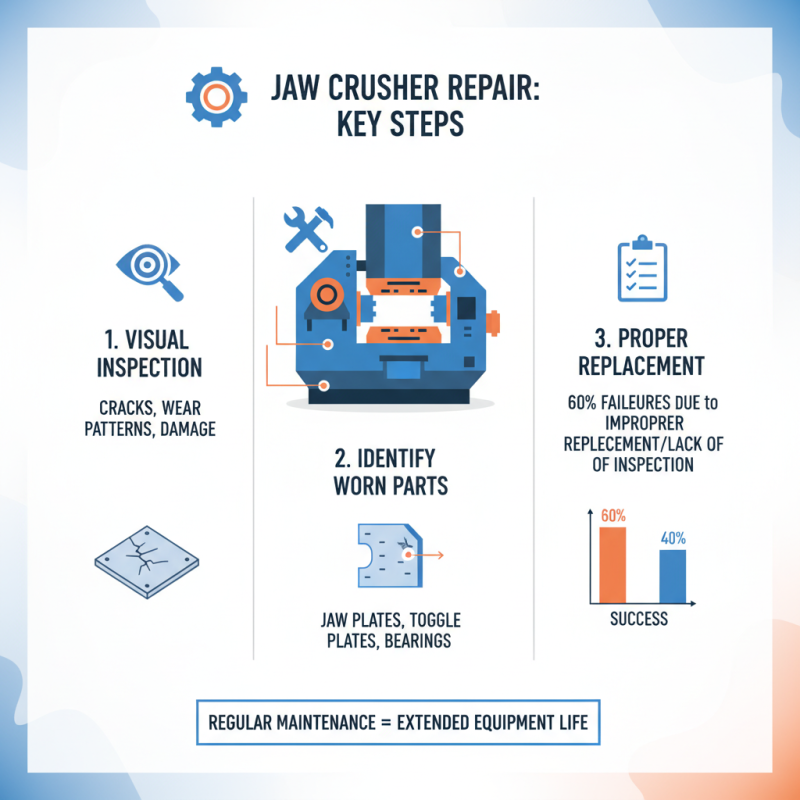

Identifying and replacing jaw crusher parts is vital for optimal performance. A well-maintained jaw crusher can enhance efficiency and prolong its lifespan. However, recognizing when parts need replacement can be a challenge. Many operators overlook subtle signs of wear, leading to costly delays.

Understanding the critical components of jaw crusher parts is essential. Jaw plates, bearings, and shafts play crucial roles in the machine's function. Regular inspections should be a priority. Take note of cracks, wear patterns, and any unusual noises. These can signal larger issues that require immediate attention.

While the process may seem straightforward, mistakes can happen. Often, parts may be misidentified, leading to incorrect replacements. This could impact the crusher's performance adversely. Reflecting on past maintenance experiences can help in improving practices. Ensuring you know how to identify and replace jaw crusher parts effectively is an ongoing journey.

Understanding the components of a jaw crusher is vital for effective maintenance and operation. Jaw crushers primarily consist of a fixed jaw and a movable jaw, both designed to crush materials between them. According to industry reports, these components experience significant wear, especially in high-volume production scenarios. The fixed jaw wears down slower than the movable jaw. This difference can lead to uneven crushing and inefficiencies in material processing.

Other essential parts include the toggle plates. They play a critical role in maintaining the desired gap between the jaws. Regular inspection is necessary, as worn toggle plates can lead to misalignment and increased operational risks. A recent analysis suggested that 15% of operational downtime in mining operations arises from equipment failure linked to neglected parts. Operators often overlook signs of wear, causing frustration and unexpected costs.

The wear plates are another critical component. They encounter repeated impacts and can degrade quickly. Replacing them can prevent further damage to the jaws and improve crushing efficiency. Industry experts recommend monitoring material output. If the output is inconsistent, it might indicate worn parts. Regular replace and maintenance practices can lead to better performance and reduce overall operational costs. However, many operators struggle with knowing when to replace components, highlighting the need for more comprehensive training and awareness.

| Component | Function | Common Issues | Replacement Frequency |

|---|---|---|---|

| Jaw Plates | Crushes material fed into the crusher | Wear and tear, cracking | Every 500-1000 hours of operation |

| Toggle Plate | Transmits power to the moving jaw | Cracks, wears down | Annually or as needed |

| Flywheel | Stabilizes the machine and stores energy | Cracks, misalignment | Every 2 years or as needed |

| Bearing | Allows smooth movement of the jaw | Overheating, excessive wear | Every 2000 hours of operation |

| Crusher Frame | Houses all components of the crusher | Cracks, deformation | Every 5 years |

Identifying wear and tear in jaw crusher parts is crucial for maintaining performance.

Observing signs like unusual noises or vibrations can indicate deeper issues. Research shows that approximately

40% of downtime in mining operations stems from component failures. Regular inspections

can catch these problems early.

Check for cracks and fractures on the jaws. A study reveals that

20% of jaw plate failures are due to fatigue. If you see uneven wear

patterns, it often means misalignment or improper installation. Such problems can lead to significant maintenance costs.

Inspecting other components, like bearings and bushings, is equally important.

Deterioration in these parts creates excess heat. This could escalate operational hazards. Regular lubrication helps,

but it may not address underlying issues. Recognizing these signs early can save both time and money in the long run.

Keeping records of maintenance can be valuable. It offers insight into patterns of wear, assisting future repairs.

Identifying faulty parts in a jaw crusher is essential for maintaining its efficiency. Start by examining the discharge area. A decrease in output size can indicate worn jaws or damaged liners. Listen for unusual sounds. A grinding noise may suggest interference between moving parts. Regular visual inspections can reveal cracks or excessive wear.

Check for signs of overheating, which might point to bearing failure. If the machine vibrates excessively, components may need attention. Take time to document any abnormalities. Tracking issues can help in determining patterns. Remember, not all signs are clear-cut. Some problems may lurk beneath the surface.

After diagnosing issues, replacing parts is crucial. Ensure you have the right tools and safety gear. Remove the damaged components carefully. Follow guides for proper installation. It's easy to make mistakes here. Look for misalignments in new parts. Over-tightening can also lead to damage. Always double-check your work for safety and efficiency.

Replacing jaw crusher parts requires specific tools and techniques. Proper identification of worn or damaged components is crucial. Visual inspections help spot cracks, wear patterns, and other damage. Maintenance reports from industry experts indicate that about 60% of equipment failures are due to improper part replacement or lack of regular inspections.

When replacing parts, essential tools include wrenches, hammers, and replacement kits. A torque wrench ensures that components are secured correctly. Industry data suggest that improper torque can reduce part lifespan by up to 30%. Using a lifting device is also important to safely handle heavy components.

One common mistake is rushing the repair process. This often leads to overlooking critical steps. Another frequent issue is not having the right replacement parts on hand. Many operations report delays when sourcing parts, causing downtime that impacts productivity. Addressing these shortcomings can improve reliability and performance significantly.

Regular maintenance is crucial for extending the lifespan of a jaw crusher. Studies show that proper maintenance can increase equipment life by 20-30%. This can lead to significant cost savings over time. Daily checks on components like wear plates, bearings, and the jaw itself are essential. Detecting issues early can prevent costly repairs and downtime.

Lubrication plays a key role in the health of the machine. Quality oils should be used, with regular intervals for application. A well-lubricated crusher can operate more efficiently. This often translates into improved productivity. However, it's common to see operators neglecting this simple task. It's easy to overlook but vital.

Another aspect is the monitoring of operating conditions. Keeping an eye on temperature and vibration can help identify potential issues. Data from industry reports suggest that more than 70% of failures could have been avoided with proper monitoring. Operators sometimes miss this, focusing more on output than maintenance. Balancing productivity with care is essential for long-term success.