-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the rapidly evolving mining and aggregates industries, optimizing equipment performance is crucial for maintaining a competitive edge. A recent report from the International Mining Association highlights that primary gyratory crushers account for approximately 30% of the total operating costs in mineral processing. This emphasizes the importance of enhancing operational efficiency through strategic management of Primary Gyratory Crusher Parts. By leveraging data-driven insights and advanced analytics, operators can monitor wear rates, reduce downtime, and improve maintenance schedules, leading to significant cost savings and productivity gains.

As the market demands more automation and smarter solutions, understanding how to effectively utilize and upgrade Primary Gyratory Crusher Parts becomes essential for maximizing throughput and ensuring long-term sustainability in operations.

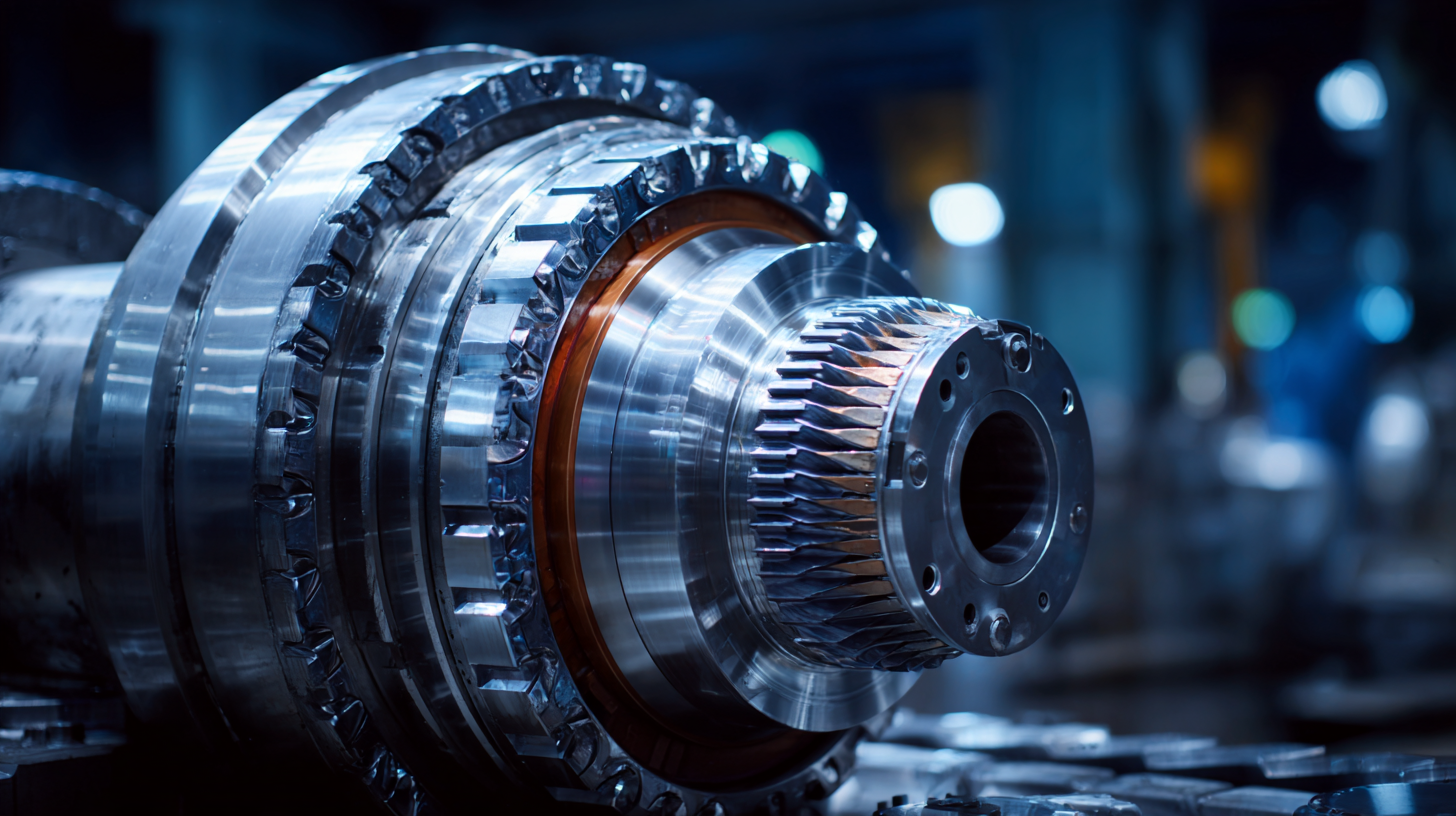

Primary gyratory crushers play a crucial role in the mining industry, serving as the backbone for processing large volumes of ore efficiently. These machines, with their robust design and high-capacity capabilities, are specifically engineered to handle the most challenging crushing tasks. Their design allows for the continuous crushing of materials, enabling operations to maintain high throughput levels while minimizing downtime. This efficiency is essential for mining operations that rely on consistent production to meet market demands.

Understanding the mechanics behind primary gyratory crushers is vital for optimizing their performance. These crushers operate through a combination of compressive force and shear stress, allowing them to break down hard materials while preserving the integrity of smaller particles. Proper maintenance and the use of high-quality replacement parts can significantly enhance their efficiency, prolonging equipment life and reducing operational costs. By prioritizing optimal performance and reliability, mining operations can ensure that their primary gyratory crushers continue to contribute to their overall success.

Primary gyratory crushers are essential in the aggregate and mining industries, known for their ability to handle large volumes and deliver exceptional efficiency. Understanding the key components of these machines can significantly enhance operational performance. The main parts include the mantle, concave liners, and the drive assembly, each playing a critical role in the machinery's capacity to crush and size materials effectively. The mantle performs the crushing action, while the concave reduces the material size, ensuring optimal particle size distribution.

Recent advancements have focused on improving the design and materials used in these components, which can lead to increased wear resistance and lower maintenance costs. The integration of innovative technologies also allows for more precise control of the crushing process, enhancing material throughput and reducing energy consumption. A thorough knowledge of these components and their functions can empower operators to optimize their equipment, resulting in superior efficiency and productivity in their operations.

| Component | Function | Material | Typical Lifespan (Hours) | Cost Estimate (USD) |

|---|---|---|---|---|

| Mantle | Crushing the materials against the concave | High manganese steel | 3000 | 4500 |

| Concave | Forms the outer surface for the crushing action | High chromium iron | 2500 | 3000 |

| Spindle | Transmits the drive force | Carbon steel | 5000 | 2000 |

| Hydraulic System | Adjusts the setting and provides additional force | Steel and hydraulic fluid | N/A | 8000 |

| Bearings | Supports rotating parts and reduces friction | Bronze or high-performance polymers | 4000 | 1500 |

In maximizing efficiency within gyratory crusher operations, data-driven approaches play a crucial role. The implementation of advanced techniques such as fast entropy multilevel variational mode decomposition facilitates effective fault diagnosis, ensuring that potential failures can be identified and addressed timely. By utilizing these data-centric methods, operators can significantly reduce downtime and enhance the overall reliability of gyratory crushers, which are essential in high-demand mining environments.

Furthermore, innovations in crushing technology are pivotal in optimizing performance. Recent advances have shown that adjusting operational parameters can lead to notable improvements in particle size distribution and energy efficiency. By adopting data analytics and embracing new technologies, mining operations can fine-tune their crushing processes, resulting in not only reduced operational costs but also a smaller environmental footprint. Emphasizing these data-driven strategies paves the way for a more sustainable and efficient future in mining and mineral processing.

Proper maintenance is crucial for enhancing the longevity of primary gyratory crusher parts. Regular inspections can help identify wear patterns and potential issues before they escalate. Operators should establish a routine maintenance schedule that covers key aspects such as lubrication, component tightening, and cleaning of the crusher. This proactive approach not only increases the lifespan of the equipment but also improves overall efficiency.

Tips: Ensure that the lubrication schedule follows manufacturer recommendations, as inadequate or excessive lubrication can lead to premature wear. Also, keep an eye on the temperature of components during operation; overheating can signal underlying problems that need immediate attention.

Another effective strategy is to train personnel on best practices for operating the machinery. Well-trained operators are more likely to follow procedures that prevent unnecessary stress on the parts, thus reducing the frequency of repairs. Moreover, utilizing advanced monitoring technologies can provide real-time data on the condition of the crusher, enabling timely interventions that further protect the equipment.

Tips: Implement a system for tracking maintenance activities and equipment performance. This data-driven approach can help identify trends and areas for improvement, ensuring that maintenance strategies evolve alongside the technology and operational demands.

Enhancing efficiency in primary gyratory crusher operations requires a deep dive into performance metrics. According to a 2022 study by the International Journal of Mineral Processing, optimizing the feed size and distribution can increase throughput by up to 15%. Monitoring parameters such as power consumption, wear rates, and output size is essential for identifying areas needing improvement. Mining operations that leverage real-time data analytics have reported a 25% improvement in operational efficiency by adjusting these parameters proactively.

Tip: Regularly track wear patterns on mantle and concave liners to prevent unexpected breakdowns. Utilizing software that integrates wear data with operational metrics can help forecast when to conduct a maintenance check.

Additionally, implementing predictive maintenance strategies based on historical performance metrics can significantly enhance reliability. The Mining Technology Review notes that predictive maintenance can reduce unplanned downtime by as much as 30%. By continuously analyzing operational data and performance trends, companies can ensure their gyratory crushers operate at peak efficiency.

Tip: Invest in advanced monitoring systems that provide insights into vibration, temperature, and load conditions. These systems can alert operators to potential issues before they escalate, ensuring smoother production flows.