-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the mining and aggregate industries, Cone Crusher Wear Parts play a crucial role in equipment efficiency. According to a report by Market Research Future, the global cone crusher market is expected to grow significantly, driven by increasing infrastructure projects. These wear parts are essential for maintaining the performance and longevity of cone crushers.

Expert Tom Johnson, a renowned figure in the mining sector, emphasizes, “Properly managed wear parts can save operational costs significantly.” This highlights the importance of selecting high-quality wear parts. However, many companies neglect regular inspections of these components, leading to costly downtime and reduced productivity.

It’s crucial for businesses to understand the implications of wear on performance. Ignoring wear parts can result in unexpected failures and operational inefficiencies. Regular evaluation ensures optimal functioning and extends the life of cone crushers. Investing in quality Cone Crusher Wear Parts is not just smart; it’s essential for long-term success in a competitive market.

Cone crusher wear parts are essential for the effective functioning of the machine. These components endure significant stress during operation. As they wear down, they can affect performance and output quality. Understanding these parts helps in maintaining operational efficiency.

There are several key wear parts in a cone crusher. The mantle and concave are critical. They crush the material into smaller pieces, but they wear out over time. Regular inspection is necessary. Operators often overlook this, leading to expensive repairs. Keep an eye on these components to avoid unexpected failures.

Another aspect to consider is the liner. It’s also subject to wear and plays a vital role in the crushing process. If it is worn unevenly, it can cause vibration and poor product quality. It’s important to reflect on the wear patterns. This can provide insights into the operational health of the machine. Regular monitoring can prevent larger issues down the line.

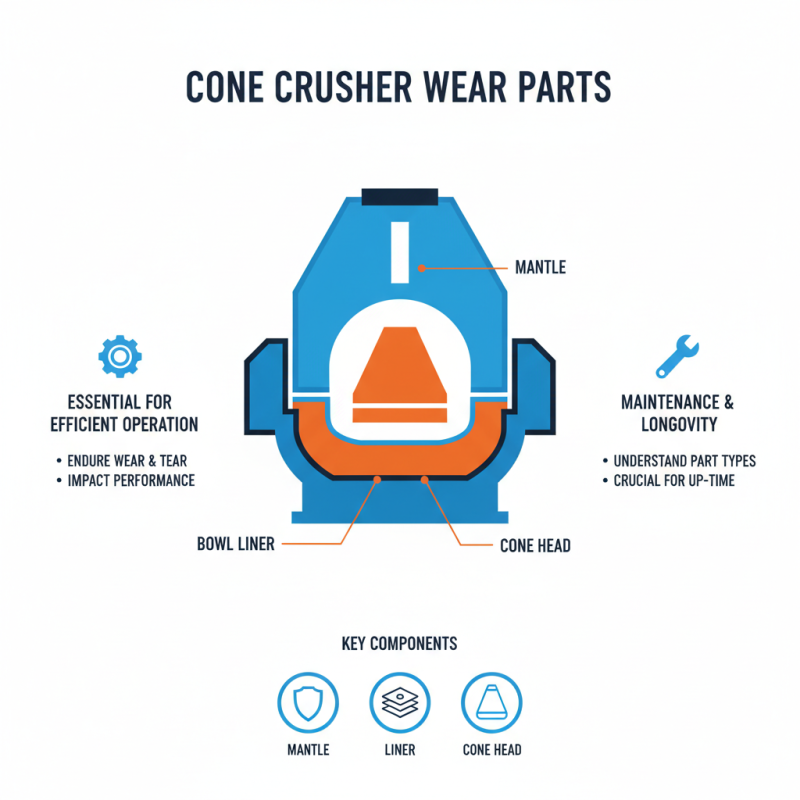

Cone crusher wear parts are critical components that experience significant wear during operation. This chart shows the importance level of various wear parts, highlighting their role in maintaining the efficiency and longevity of the cone crusher.

Cone crusher wear parts are essential for efficient operation. They endure significant wear and tear, impacting overall performance. Understanding the types of wear parts is crucial for maintenance and longevity. The main components include mantles, liners, and cone heads. Each part serves a specific function in the crushing process.

Mantles are the primary wearing surfaces, shaped to crush materials. They often need replacement after several working hours. Liners protect the crusher's frame, absorbing impacts. They may require frequent checks due to wear rates of up to 30% during regular use. Cone heads also wear down but at a slower rate, contributing to the overall efficiency of the cone crusher. A report from a leading mining equipment industry analyst states that proper management of these parts can boost productivity by 15% or more.

Monitoring the wear levels of these components is critical. Neglecting wear can lead to catastrophic failures and downtime. Yet, many operators overlook the early signs of wear. This reality calls for better training and awareness. Despite advancements in manufacturing, wear parts are not infallible. Regular inspections should be done to assess the condition of each part. Balancing workload and wear life is an ongoing challenge for operators in the field.

The wear of cone crusher parts can significantly impact the efficiency of operations. Several factors contribute to this wear. Material quality is crucial. Harder materials tend to lead to faster wear rates. However, softer materials can also create challenges. They might not withstand the crushing process effectively. Finding a balance can be difficult.

Another important factor is the type of application. For example, finer materials often require different settings. This can lead to increased wear if not managed properly. Additionally, environmental conditions play a role. Dust, moisture, and temperature fluctuations can affect how wear occurs. Regular maintenance is vital. Not paying attention can result in early failures and increased costs.

Operational techniques also matter. Operators must be trained to handle the equipment correctly. Misuse can lead to uneven wear. Sometimes, replacing parts before they are fully worn may seem unnecessary. However, it can prevent more significant issues later on. In conclusion, understanding the factors affecting wear is essential for longevity and efficiency.

Quality wear parts in cone crushers are essential for optimal performance. These components experience significant wear due to the crushing process. They directly affect the efficiency and lifespan of the machinery. Using durable materials can minimize downtime. When wear parts fail, production halts, causing costly delays.

Proper maintenance of wear parts ensures consistent output. Operators must inspect and replace these components regularly. Unexpected failures can lead to accidents and increased repair costs. Investing in high-quality parts reduces overall expenses in the long run. It’s a decision that pays off in efficiency and safety.

Not every wear part performs equally. Some may wear out faster than others, even under similar conditions. It’s crucial to assess the specific needs of your operations. The right choice can enhance throughput and reliability. Quality wear parts are not just an expense; they are an investment in future productivity.

Maintaining cone crusher wear parts is crucial for optimal performance. Regular inspections can prevent unexpected downtime. Look for signs of wear on the mantle and concave. Even minor damage can lead to significant issues over time. Always check for cracks or deformations. These inspections should be part of a routine maintenance schedule.

Proper lubrication is essential. Use the correct type and amount of lubricant. Insufficient lubrication may cause excessive wear. Clean the components regularly to remove dust and debris. Neglecting this can lead to overheating. Monitor the temperature closely during operation. Keeping an eye on these details can save costly repairs later.

Replacement of worn parts is inevitable. Don't wait for full failure to act. Schedule replacements based on usage and wear indicators. Using worn-out parts strains the entire machine. This is a common oversight that can lead to cascading failures. Addressing wear early can lead to improved crusher efficiency.