-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

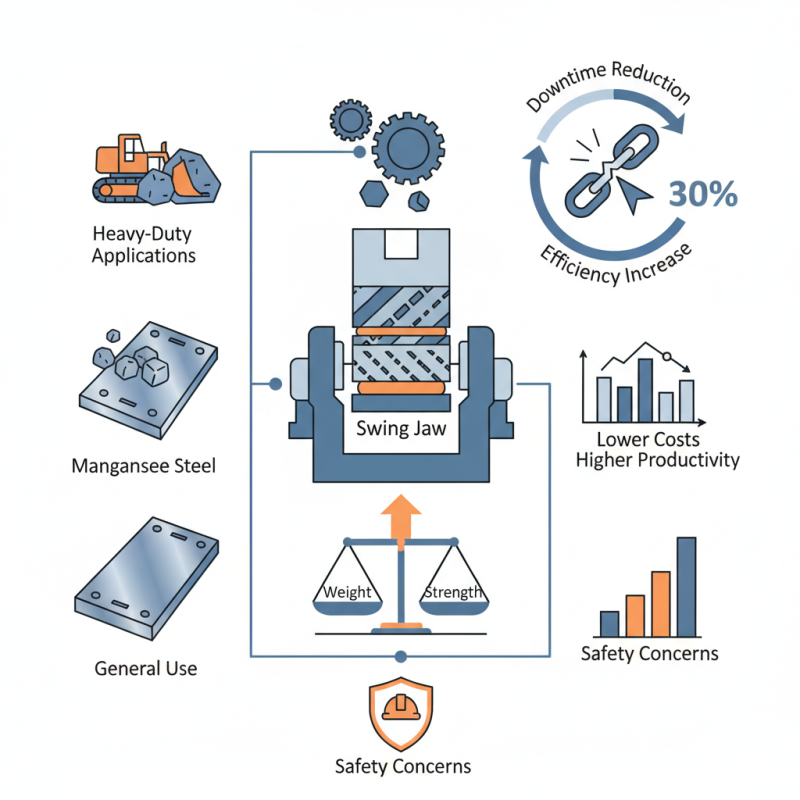

When selecting a Swing Jaw Crusher Plate, understanding your specific needs is crucial. The right plate can significantly impact efficiency and durability. According to the Minerals Council, the global mining industry sees an average of 30% downtime due to equipment failure. This highlights the importance of choosing high-quality components.

Swing Jaw Crusher Plates vary in design, material, and thickness. For instance, manganese steel plates offer excellent wear resistance, making them popular in heavy-duty applications. A report by the Mining Industry Data shows that improper plate selection can lead to increased costs and lower productivity.

Inconsistent quality often leads to performance issues. Maintaining a balance between weight and strength is essential. The wrong choice may require frequent replacements. This not only impacts operational efficiency but also raises safety concerns in the workplace. Careful consideration of your specific requirements and industry standards will guide you in making an informed decision.

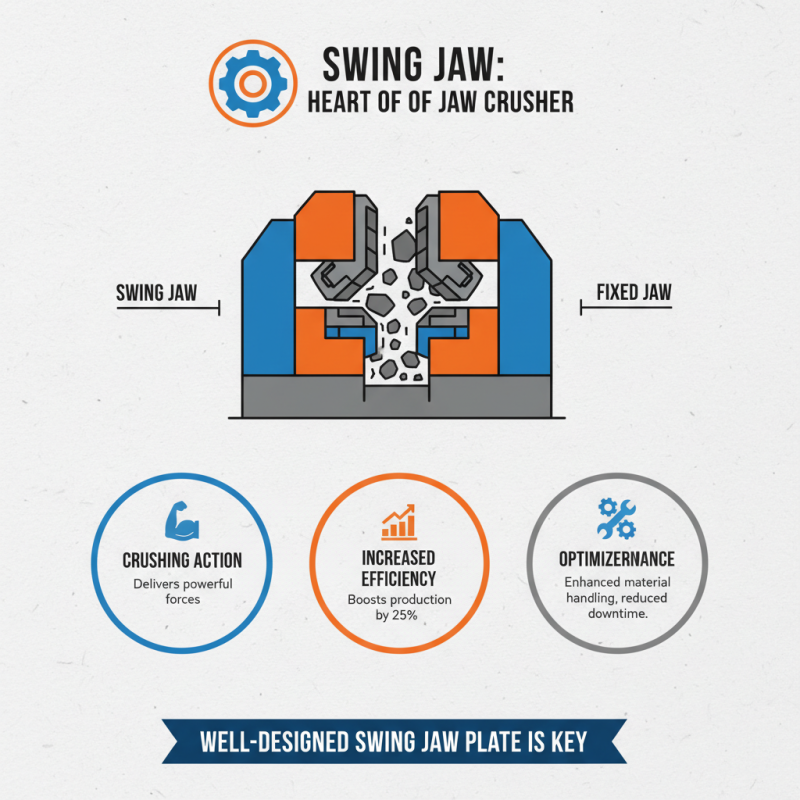

The swing jaw plays a crucial role in the operations of a jaw crusher. It is responsible for the crushing action, delivering powerful forces that break down materials. According to industry reports, the efficiency of a swing jaw can impact production rates by up to 25%. A well-designed swing jaw plate enhances material handling and reduces downtime.

When selecting a swing jaw plate, consider its shape, material, and hardness. A plate too hard may wear quickly, while one too soft may deform under pressure. Studies show that manganese steel is commonly used due to its excellent wear resistance. However, it may not suit all applications. The right balance is essential.

Different operational environments demand unique swing jaw configurations. For instance, recycled materials require different specifications compared to hard rock applications. Misjudging these aspects can lead to inefficient crushing and increased operational costs. It's vital to assess specific needs before making a selection.

Swing jaw crushers are versatile machines capable of processing various materials. These crushers are commonly used to break down hard rock, ore, and minerals. Their powerful design allows for the efficient crushing of materials like granite and basalt. These stones are tough, making them ideal for testing the durability of your crusher's jaw plate.

In addition to hard rocks, swing jaw crushers handle softer materials too. Limestone and sandstone are often processed in construction and industrial applications. These materials require less force during crushing. However, the type of jaw plate matters significantly. Choosing the right plate ensures optimal performance.

It's important to reflect on the materials you plan to process. Each material has a different hardness and abrasiveness. These factors affect the wear and tear on the jaws. Using the wrong type of jaw plate may lead to inefficiencies. It might also result in higher maintenance costs. Consider your specific needs to select the most suitable swing jaw plate.

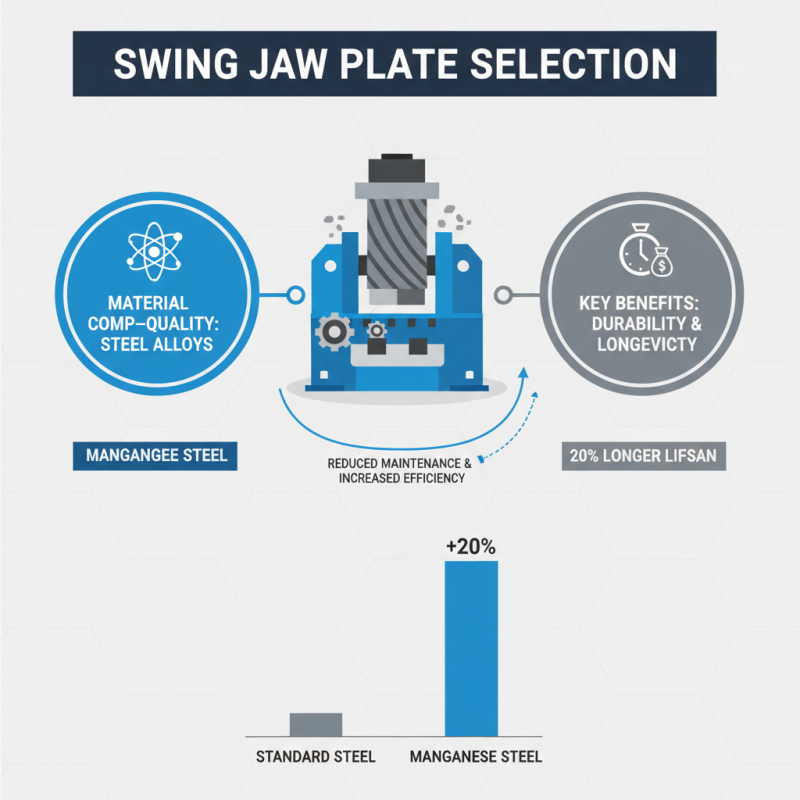

When selecting a swing jaw plate, several key factors come into play. The material composition is crucial. High-quality steel alloys often provide optimal strength and durability. According to industry reports, plates made from manganese steel can last up to 20% longer than those made from standard steel. This longevity directly impacts maintenance costs and production efficiency.

The design of the jaw plate also matters. Geometry affects the crushing process. A properly designed plate can improve the material flow and reduce blockages. Reports show that a well-engineered swing jaw plate can enhance throughput by as much as 30%. It’s important to evaluate your specific crushing needs before making a choice.

Moreover, the compatibility of the jaw plate with your existing system cannot be overlooked. A mismatch can lead to inefficiencies or even equipment failure. Often, users overlook this detail, leading to unexpected downtime. Regularly reviewing performance data and crusher wear can provide insights into whether a change is necessary. Balancing the right material, design, and compatibility is essential for optimizing your crushing operation.

When selecting a swing jaw crusher plate, understanding the various designs is critical. Each design offers unique advantages. Some plates are engineered for high wear resistance. Others focus on delivering enhanced crushing capacity. This diversity makes it essential to analyze your specific needs.

For instance, a thicker plate may resist wear better but could reduce crushing efficiency. Conversely, a lighter plate might boost output but wear down quickly. It’s important to consider these trade-offs. Failure to analyze the appropriate balance could lead to inefficient operations. In some cases, users may experience fractures due to inadequate material choice.

Looking deeper into the materials used reveals more choices. Some plates incorporate advanced alloys. Others rely on traditional cast materials. The decision impacts not just durability but also operational costs. Reflecting on one’s unique production goals can guide the right choice. Ultimately, the ideal swing jaw plate aligns with both performance and longevity.

Swing jaw crusher plates are crucial for the efficiency of your machine. Regular maintenance can significantly extend their lifespan. Start by inspecting the plates for any signs of wear or damage. Even minor cracks can lead to serious issues over time. Address these problems promptly to avoid costly repairs.

Cleaning is another vital aspect of maintenance. Dust and debris can accumulate, leading to unnecessary friction. Use appropriate cleaning agents to remove any buildup. This should be done regularly to ensure optimal performance.

Lubrication is just as important. Apply the right type of lubricant to reduce wear. Remember, neglecting these simple tasks can result in premature failure of your plates.

Monitoring the performance of your swing jaw crusher is essential. If you notice unusual noises or reduced efficiency, it may be time to reassess your maintenance routine. Keeping detailed records can help identify patterns. This reflection can guide you in making necessary adjustments. Regular check-ups are often overlooked but are key to longevity.