-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right type of jaw crusher for your project is crucial. The market offers various types. Each type of jaw crusher has unique features. These features can significantly impact your project's success.

Consider your specific needs. Types vary in size, power, and design. A small project may require a compact model. Larger operations may need heavy-duty units. It’s easy to overlook critical details in specifications. Rushing into a decision might lead to costly mistakes later.

Researching different types of jaw crushers is essential. Understanding the functions will save time and money. Seek expert advice if needed. The right type of jaw crusher can enhance efficiency. Aim for long-term performance based on your project requirements.

Choosing the right type of jaw crusher is crucial for project success. Factors like material type and site conditions can greatly affect your choice. For instance, hard materials may require a heavy-duty crusher to ensure efficient processing. A recent industry report shows that a jaw crusher's efficiency can drop by 30% if it is ill-suited for the material.

Another important consideration is the capacity. Each project will demand a specific output. A crusher's capacity is measured in tons per hour. Selecting a machine with insufficient capacity can lead to bottlenecks. In contrast, an oversized crusher may waste energy and resources. It's vital to strike a balance based on your project requirements.

Maintenance requirements are often overlooked. Some jaw crushers are easier to maintain than others. This can be a significant factor in long-term operational costs. A detailed analysis of maintenance schedules can reveal hidden costs. Ensuring access to spare parts should also be part of your decision-making process. The right choice can save time and avoid disruptions down the line.

| Factor | Consideration | Impact on Choice |

|---|---|---|

| Material Type | Hardness, abrasiveness, and size of the material | Determines jaw design and material selection |

| Feed Size | Maximum size of incoming material | Influences the jaw crusher's opening dimensions |

| Production Rate | Required output in tons per hour (tph) | Determines the size and power of the crusher |

| Crushing Ratio | Desired reduction in material size | Influences jaw design and operational parameters |

| Budget | Total budget for the equipment | Determines brand and model options available |

Choosing the right jaw crusher depends on your project needs. There are several types available, each with distinct advantages. The most common types include the single toggle and double toggle jaw crushers. The single toggle offers a simple design, which is easier to maintain. It's efficient for hard materials, but may struggle with larger rocks.

Double toggle jaw crushers have a more complex design. They provide a more efficient crushing process thanks to their dual motion. This type can handle larger materials better. However, they also require more maintenance.

Understanding the material size and hardness is crucial. Evaluate your project's requirements carefully.

Consider the output size you need. If you require a fine crush, adjust the crusher settings accordingly. Think about your operation environment too. A portable version may be suitable for remote sites. Each choice has its pros and cons. Reflect on the long-term costs and maintenance involved as well.

Choosing the right jaw crusher hinges on understanding the material characteristics of what you're processing. Materials can vary widely in their hardness, abrasiveness, and size. According to industry reports, compressive strength plays a crucial role. For instance, materials with a compressive strength exceeding 150 MPa may need heavy-duty crushers.

When analyzing materials, keep particle size distribution in mind. If pieces are too large for the crusher's feed opening, it can hinder performance. A study indicated that a mismatch can lead to a decrease in throughput by as much as 25%. Pay attention to the moisture content, as wet materials can cause clogging and operational inefficiencies.

**Tip:** Conduct a thorough analysis of your raw materials before selection. Take samples and test them to get an exact understanding of their properties. A small miscalculation can lead to significant operational issues.

Also, consider wear rates. The crusher's material needs to withstand prolonged grinding. You might find that some materials wear down the crusher parts faster than expected. A 2019 report revealed that some materials can lead to 50% increased wear in just six months of operation.

**Tip:** Regularly monitor wear patterns during initial phases. Adjustments may be needed based on actual operational data. Be prepared to rethink your choice if wear rates exceed anticipated levels.

When selecting a jaw crusher, understanding capacity and size requirements is crucial. The capacity of a jaw crusher is often measured in tonnes per hour (tph). For example, a typical unit can handle anywhere from 50 tph to over 1,500 tph, depending on the model and settings. Industry reports indicate that selecting a crusher that suits your project's capacity needs can enhance productivity and minimize operational costs.

Size considerations begin with the feed opening. A larger feed opening allows for bigger rocks to enter, which can boost capacity. Standard sizes range from 10 inches to over 36 inches. The crusher's size should match the material size and the desired output. Proper alignment of the jaw and consistent feed rate are essential. Lagging in these areas can lead to inefficient crushing and increased wear on parts.

It's also important to factor in the material's hardness and abrasiveness. For instance, softer materials may require less power, while harder materials could demand larger and more robust machines. Research suggests that an ill-suited jaw crusher can lead to overloading and increased downtime. Ensure your choice reflects a careful assessment of both capacity and size to optimize performance and longevity.

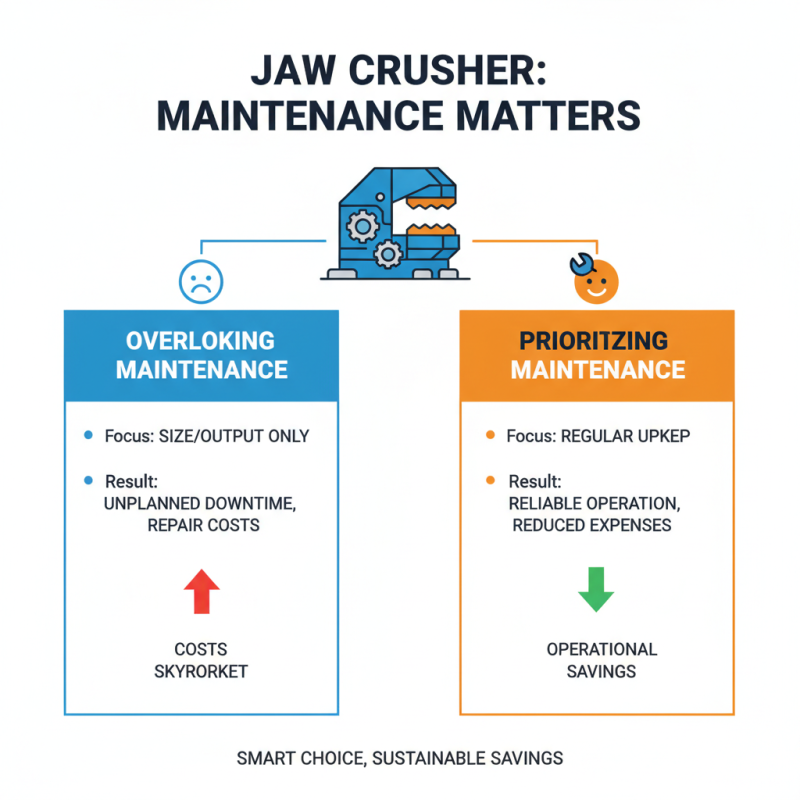

When selecting a jaw crusher, maintenance needs are critical. Regular upkeep can significantly influence operational costs. Sometimes, operators may overlook this aspect. They might buy a machine based solely on size or output. However, if maintenance is neglected, the costs can skyrocket. A poorly maintained crusher can lead to unexpected breakdowns and repairs.

Consider the ease of access for maintenance. Some models offer better designs for quick part replacements. This can save both time and resources. Additionally, operational costs must be calculated carefully. Fuel consumption, wear parts, and downtime impact your budget. Choosing the wrong type might lead to excess costs in the long run. Reflect on the total cost of ownership before making a decision. Assessing these factors ensures a more informed choice. Investing time in planning can prevent future headaches.