-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

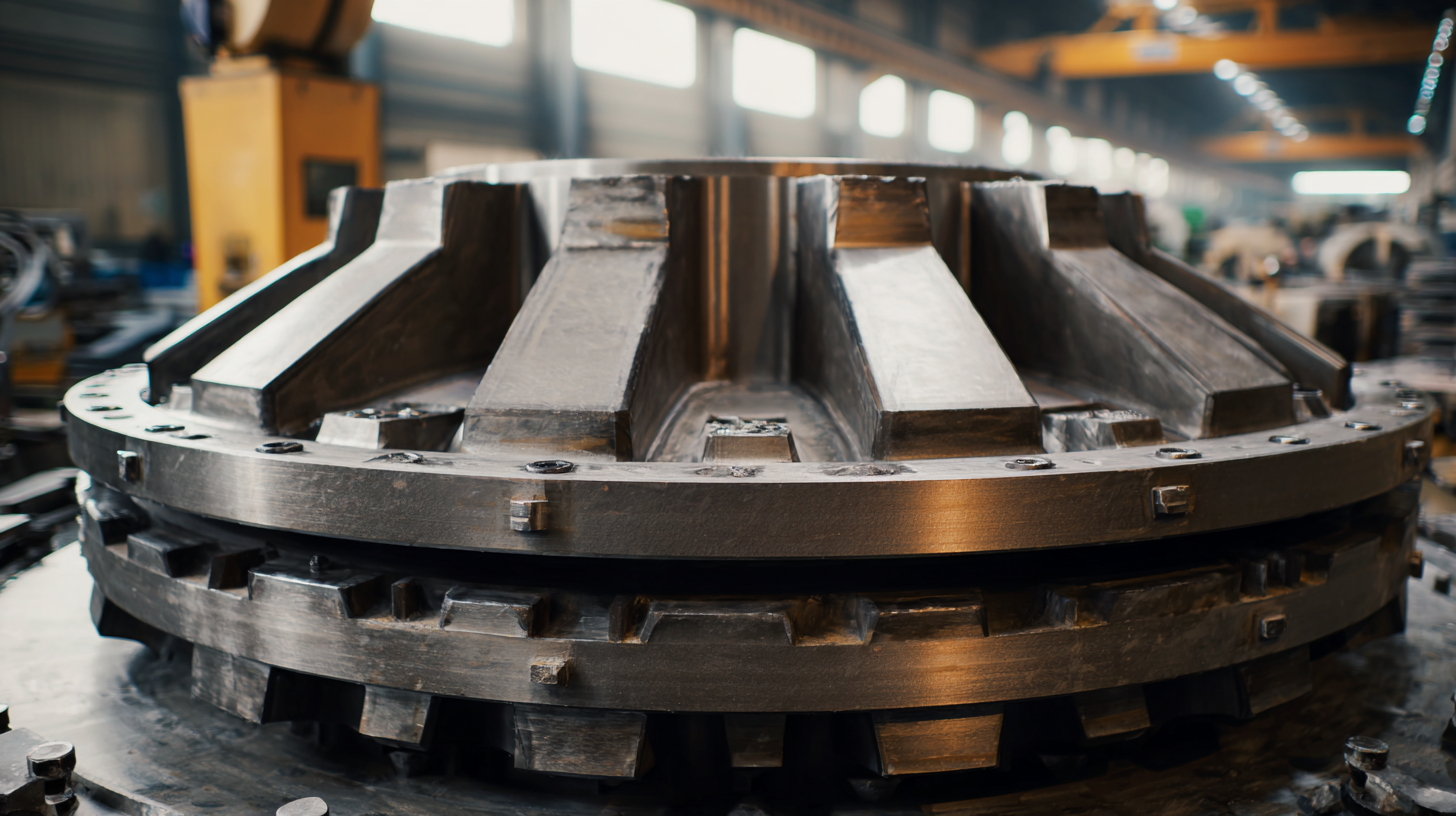

The Bowl Liner Cone Crusher has emerged as a pivotal component in the mining and aggregate industries, enhancing efficiency and production rates significantly. According to a recent report by Industry Research, the global cone crusher market is projected to reach USD 2.6 billion by 2027, growing at a CAGR of 5.1% from 2020 to 2027. Innovations in bowl liner materials and designs are crucial for minimizing wear and maximizing lifespan, leading to reduced operational costs. Furthermore, advancements such as the implementation of 3D printing technologies and the use of high-performance alloys have substantially increased the durability of these components, ensuring optimal performance even under the most demanding conditions. By understanding the innovations surrounding Bowl Liner Cone Crushers, operators can leverage these benefits to enhance their crushing processes and drive business growth.

The design of bowl liners in cone crushers plays a crucial role in the efficiency and effectiveness of the crushing process. Recent innovations have focused on enhancing the durability and performance of bowl liners, addressing issues such as wear resistance and material composition. Advanced materials such as high-manganese steel and ceramic composites are used to optimize the strength and longevity of the liners, allowing them to withstand the harsh conditions of mining and aggregate processing.

Moreover, the geometry of bowl liners has seen significant improvements. New designs incorporate features that enhance the flow of material, reducing bottlenecks and ensuring a more uniform crushing action. Innovations such as variable profiles have been developed, which allow for adjustments based on the particle size and material characteristics. These enhancements not only prolong the lifespan of the bowl liners but also increase overall productivity, contributing to more efficient operations in various industries.

Upgraded bowl liners in cone crushers represent a significant leap in enhancing overall crusher efficiency. By employing advanced materials and innovative designs, these liners significantly improve wear resistance and operational longevity. This not only reduces maintenance costs but also translates to less downtime, allowing for a more consistent production schedule. The effective design of bowl liners ensures optimal crushing performance, accommodating a wider range of feed materials and sizes while maintaining product quality.

Furthermore, the benefits of upgraded bowl liners extend to energy consumption and productivity. Enhanced liner designs can lead to better load distribution and fewer energy losses during the crushing process. This optimization results in lower energy costs and higher throughput, maximizing the return on investment for mining and aggregate operations. As a crucial component in the crushing circuit, investing in high-quality bowl liners can yield substantial gains in both efficiency and profitability in the long run.

In recent years, the cone crusher industry has seen significant advancements in materials used for bowl liners, which are crucial for enhancing the durability and performance of these machines. According to a 2022 report by MarketsandMarkets, the global cone crusher market is projected to reach USD 2.3 billion by 2026, driven in part by innovations in wear parts, including bowl liners. Manufacturers are increasingly adopting high-manganese steel, alloy steels, and even advanced ceramic composites to extend the lifecycle of these components, improving resistance to deformation and wear.

Notably, the introduction of hybrid materials that combine both traditional and modern elements has proven beneficial. A study from the Mining Industry Institute indicates that these innovative bowl liners can reduce wear rates by up to 30% compared to standard liners, thereby lowering maintenance costs and increasing operational efficiency. Furthermore, ongoing research into nanotechnology is paving the way for custom coating solutions that enhance smoothness and reduce friction, allowing for better crushing performances while minimizing energy consumption, which is a crucial consideration as industries move towards more sustainable practices.

Maintaining the longevity of cone crusher liners is crucial for maximizing productivity and minimizing costs in mining and aggregate industries. One of the best practices for maintenance is regular inspection. By routinely checking the liners for signs of wear or damage, operators can take remedial action before excessive wear leads to more costly replacements. Additionally, monitoring the feed material for size and composition can help in adjusting operational parameters to reduce unnecessary strain on the liners.

Another essential aspect of extending the life of cone crusher liners is optimizing the crusher's operational settings. Properly adjusting the crusher gap and maintaining the correct speed can reduce wear by ensuring that the liners are engaged with the material in an efficient manner. Implementing a proactive maintenance schedule, which includes the timely replacement of worn liners and the use of high-quality materials, is also vital. By embracing these best practices, operators can significantly enhance the durability of cone crusher liners, leading to improved equipment performance and lower total operating costs.

| Dimension | Value | Notes |

|---|---|---|

| Liner Material | Manganese Steel | High durability and wear resistance |

| Average Lifespan | 400-800 hours | Varies based on application and maintenance |

| Maintenance Frequency | Weekly | Regular checks prolong liner life |

| Wear Indicator | Yes | Allows for easy monitoring |

| Temperature Monitoring | Critical | Prevents overheating and damage |

| Dust Control Measures | Required | Reduces wear and improves health & safety |

Selecting the right bowl liner for a cone crusher is crucial for achieving optimal performance and durability. Several factors must be taken into account when making this choice. Firstly, the material composition of the bowl liner plays a significant role; options such as manganese steel or alloy steel can greatly influence wear resistance and overall lifespan. It’s essential to choose a material that aligns with the specific requirements of the crushing application, as different materials offer varying levels of toughness and resilience.

Additionally, the design of the bowl liner is another key consideration. The profile and shape of the liner affect the crushing process, impacting the efficiency and output of the crusher. Selecting a liner that complements the specific type of rock or material being processed can enhance the crushing capabilities and minimize downtime associated with liner changes. It's also important to consider the compatibility of the bowl liner with the existing cone crusher model, ensuring a proper fit and optimal crushing performance. By evaluating these factors, operators can make informed decisions that lead to improved productivity and reduced operational costs.