-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the ever-evolving landscape of mining and aggregate industries, the quality of Cone Crusher Wear Parts remains a crucial factor. Renowned expert John Smith emphasizes, "Choosing the right wear parts can significantly boost crusher efficiency." This highlights the importance of selection and maintenance in enhancing performance.

Cone Crusher Wear Parts impact productivity. They experience severe conditions, leading to wear and tear. The right materials and designs minimize downtime and maximize output. Companies often overlook the need for regular assessments and upgrades. Investing in high-quality components is not just a recommendation; it's essential.

Many operations still use outdated parts. This can lead to inefficiencies and increased costs over time. Regularly evaluating and updating wear parts can save resources and improve overall performance. As the industry progresses, staying informed on advancements in Cone Crusher Wear Parts is vital for success.

Cone crushers are vital in the mining industry. They break down various materials effectively. Understanding wear parts is crucial for optimal performance. These components endure high levels of stress and wear. Regular monitoring can prevent expensive breakdowns.

Key wear parts include the mantle and concave. They directly impact crushing efficiency. Choosing the right materials for these parts is essential. High-quality options can lead to better productivity. Yet, it's common to overlook their condition until problems arise. Operators should cultivate awareness for proactive maintenance.

Incorporating advanced materials can enhance durability. Some operators may hesitate to invest upfront. However, short-term savings might lead to long-term issues. Taking time to assess wear parts is never wasted. A thoughtful approach can significantly boost overall output in any operation.

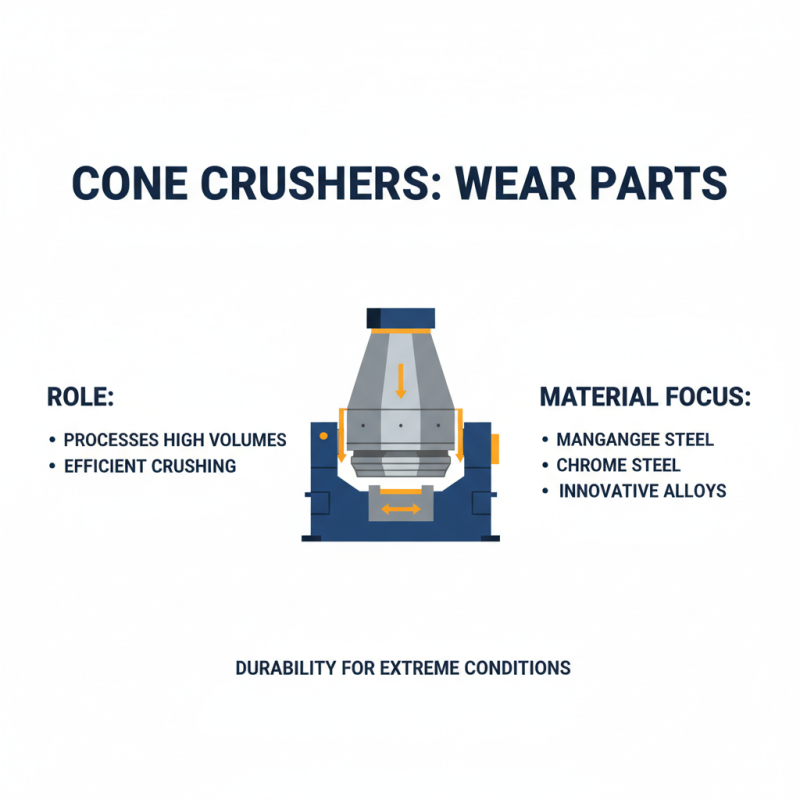

In the realm of mining and aggregate industries, cone crushers are essential. They handle high volumes of material with exceptional efficiency. To maintain optimal performance, wear parts must be made from high-quality materials. Commonly used materials include manganese steel, chrome steel, and even innovative alloys. These materials provide the durability that equipment needs under extreme conditions.

Manganese steel is particularly favored for its hardness and impact resistance. Reports suggest that it can withstand tough crushing applications while maintaining shape and integrity. Chrome steel, on the other hand, offers excellent resistance to wear. It is useful for components that experience both impact and abrasion. However, many wear parts struggle with fatigue over time. This leads to downtime that can be costly.

It's important to evaluate wear part lifespans. Current industry data indicates that proper material selection can increase service life by as much as 30%. Yet, many operations fail to analyze performance gaps. Without regular assessments, inefficiencies can persist. Understanding key wear materials is critical for any business aiming for longevity in asset performance.

As the industry approaches 2026, the demand for efficient and durable cone crusher wear parts continues to evolve. Innovations are emerging to meet the challenges faced in high-production environments. New materials, such as advanced alloys and composites, are being utilized to enhance the lifespan of these components. This attention to material science is crucial; however, the real test will come in performance under extreme conditions.

Furthermore, manufacturers are exploring designs that optimize the flow of materials. Improved geometry can lead to higher efficiency and reduced wear. Yet, these advancements often come with a learning curve. Operators may need to adjust their maintenance schedules. Being proactive in monitoring wear patterns becomes essential. The integration of smart technologies, like IoT sensors, can also play a role, but reliability varies across applications.

While trends are promising, challenges persist. Not all innovations yield the expected results in different environments. Cost remains a concern for many operators. Balancing investment in new parts and achieving a return on that investment is not always straightforward. The industry will need to weigh these factors carefully as it moves towards 2026.

Measuring the efficiency of cone crusher parts involves analyzing performance metrics that reflect their operational effectiveness. Key indicators include throughput, reduction ratio, and wear rate.

Throughput measures how much material the crusher can process in a given time. A high throughput indicates a well-functioning system. However, it’s essential to consider that increased output may lead to faster wear and tear.

Reduction ratio is another vital metric, showing how much the size of the material is reduced from input to output. A well-optimized reduction ratio enhances the overall crushing process. If the ratio is too low, it may suggest inefficiencies in the crushing circuit. This can prompt a reflection on adjustments needed for optimal performance.

Wear rate gives insight into how quickly parts degrade. A lower wear rate translates to longer-lasting parts. But, it can also indicate the need to reevaluate material hardness or operational settings. Frequent inspections and careful monitoring are crucial. This helps in balancing performance with the wear of components, ensuring sustained efficiency over time.

In the competitive world of mining and construction, the choice of wear parts is crucial. Upgrading to high-quality cone crusher wear parts can significantly enhance performance. A recent industry report from the Mining Journal indicates that using premium materials leads to a 30% increase in lifespan for these components. This reduction in replacement frequency lowers operational costs over time.

However, the initial investment can be daunting. The cost of high-quality wear parts may be double that of standard options. Yet, many companies see a return on investment within six months due to reduced downtime and maintenance costs. A study from the Construction Equipment Manufacturers Association found that better wear parts can reduce overall maintenance costs by up to 40%.

On the flip side, not every upgrade yields immediate results. Some operators might discover that compatibility issues arise with existing machinery. Furthermore, wear parts may not perform as expected in certain environments. Therefore, before upgrading, a thorough analysis of specific operational needs is essential. Balancing cost and performance is an ongoing challenge in this industry.