-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of mining and aggregate production, Cone Crusher Parts play a critical role. Renowned expert Dr. John Smith, a leading authority in crusher technology, once stated, "Quality parts can drastically improve crusher performance." This highlights the importance of selecting the right cone crusher components.

Investing in high-quality Cone Crusher Parts ensures operational efficiency. However, many companies underestimate this crucial aspect. They often choose cheaper options, which may lead to frequent replacements and increased downtime. It's essential to focus on durability and compatibility with specific models.

As the industry evolves, so do the demands for cone crusher parts. Innovations are on the horizon, yet relying on outdated knowledge remains common. The challenge lies in understanding how to balance cost, quality, and innovation. Beaching through this intricate landscape requires both commitment and insight.

In 2026, understanding the key components of cone crusher parts is essential for efficient operations. The mantle is crucial. It spins around the shaft and crushes materials. The wear on this part can influence performance drastically. Regular inspections should be routine; signs of wear can be subtle yet impactful.

The bowl liner, another important component, houses the crushed material. Its shape affects how materials are processed. An ill-fitting bowl liner can cause leakage of material. Operators must ensure proper installation. A thorough check can save time and resources in the long run.

The hydraulic system plays a vital role too. It allows for adjustment of the crusher's settings. However, hydraulic issues can arise unexpectedly. Regular maintenance is essential to prevent costly downtime. Operators should be prepared for challenges, as not all systems perform flawlessly.

The world of cone crusher parts is evolving rapidly. Recent innovations focus on materials that enhance durability and performance. For example, high-strength alloys are now more common. These materials resist wear and tear, extending the life of each component. This is crucial for ensuring lower maintenance costs.

In addition, advancements in metallurgy have led to lighter parts. These components improve overall efficiency by reducing operational strain. However, the challenge remains in balancing weight and strength. Engineers are continually refining these designs. They often conduct tests to evaluate the performance of new materials. Failure is part of the process, and each iteration sheds light on potential weaknesses.

There are also emerging treatments for existing materials. Techniques like surface hardening and coating can significantly enhance resistance to abrasion. Yet, not all treatments yield the desired results. Some solutions may lead to brittle materials, which can fail unexpectedly. This highlights the necessity for ongoing research and development in this field.

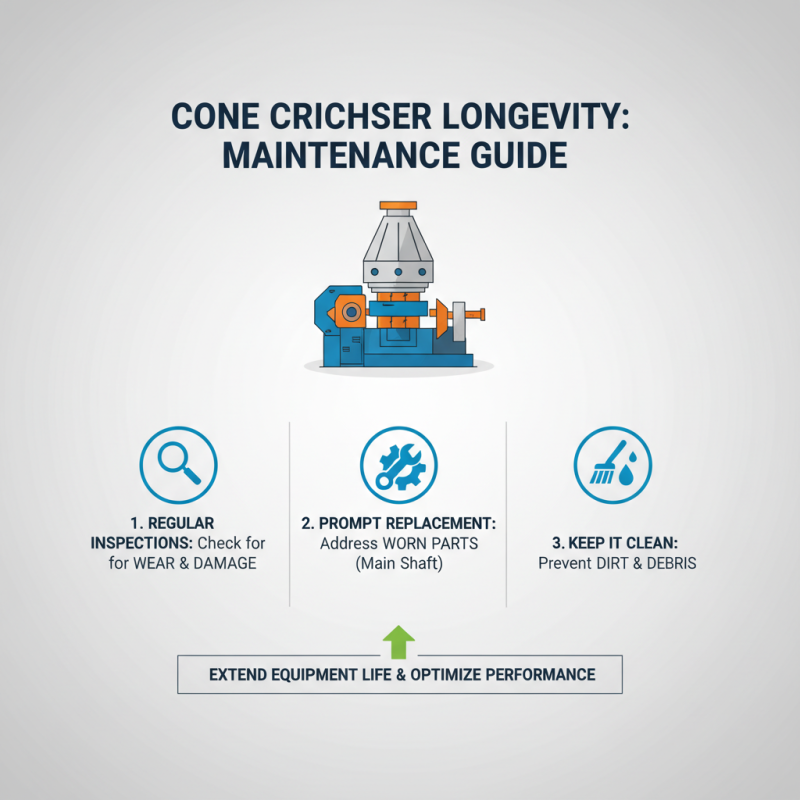

Proper maintenance is crucial for extending the life of cone crusher parts. Regular inspections can help identify wear and tear. Check the main shaft for any signs of damage or misalignment. Replace worn parts promptly to avoid further issues. Keeping your equipment clean will also aid in optimal performance. Dirt and debris can lead to premature wear.

Lubrication plays a significant role in maintenance. Ensure that the bearings receive the right amount of lubricant. Too much or too little can result in problems. Monitor the temperature of the bearings; excessive heat can indicate a problem. Cleaning oil filters should be a routine task to maintain proper flow.

Training operators on best practices is essential. They should know how to operate the machine effectively. Improper use can lead to unnecessary wear. Regular workshops can promote awareness. Remember, even the best parts need attention to remain effective. Taking these steps can help prevent costly repairs or replacements.

Choosing the right cone crusher parts is crucial for optimal performance. Different applications need specific parts to achieve efficiency. For instance, the material size, type of rock, and desired output determine the choice of parts.

When selecting parts, focus on quality over price. High-quality materials last longer and require less frequent replacements. However, sometimes cheaper options can perform surprisingly well. It’s essential to weigh the benefits and drawbacks of each part.

**Tip:** Always consult with experts to ensure you make informed decisions.

Regularly inspect parts for wear and tear. It’s easy to overlook minor damage, but it can escalate quickly. A damaged part can affect the entire crushing process.

**Tip:** Create a maintenance schedule. Regular checks can prevent significant breakdowns.

Also, pay attention to compatibility. Parts must fit your specific model. Mismatched components can lead to operational issues. Remember, finding the right cone crusher parts is a balance of performance and practicality.

This chart illustrates the usage frequency of different cone crusher parts in 2026. The mantle and concave are the most frequently used parts, indicating their importance in crusher performance.

Cone crushers are essential in the mining and construction industries. They break down large rocks into smaller, more manageable pieces. The parts that make up these machines play a crucial role in their efficiency and reliability. Understanding the top manufacturers of cone crusher parts is vital for operators.

In recent years, industry reports have shown a growing demand for high-quality cone crusher parts. A report by Industry Research claimed that the global cone crusher market is projected to reach over $16 billion by 2026. Key players are focusing on durable materials to enhance longevity. However, some manufacturers still cut corners, leading to performance issues.

Another study highlighted that around 30% of parts fail due to poor quality. This emphasizes the importance of sourcing from reputable suppliers. Operators should seek out companies that offer comprehensive warranties and support. Not all manufacturers provide these guarantees. Being educated on the specific needs and challenges of cone parts can lead to improved operational efficiency.

| Part Name | Material | Application | Durability (Hours) | Maintenance Interval (Hours) |

|---|---|---|---|---|

| Mantle | High Manganese Steel | Primary Crushing | 1000+ | 400 |

| Concave | Alloy Steel | Secondary Crushing | 800+ | 500 |

| Bowl Liner | Chrome-Molybdenum Steel | Tertiary Crushing | 1200+ | 600 |

| Hydraulic Cylinder | Steel | Adjustable Crush | N/A | N/A |

| Spring | Alloy Material | Pressure Relief | N/A | N/A |