-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the quest for enhanced productivity in mining and aggregate industries, the importance of the Cone Crusher Bowl Liner cannot be overstated. This component directly influences the efficiency of cone crushers. Selecting the right bowl liner can lead to increased output and reduced downtime.

In 2026, various options for Cone Crusher Bowl Liner will be available. Each option presents unique features that cater to different crushing applications. Choosing the wrong type can result in premature wear or inefficient crushing. Operators must pay close attention to materials and designs that best match their needs. Some bowl liners may not perform as expected under certain conditions.

Understanding the critical role of the Cone Crusher Bowl Liner is essential for achieving long-term success. Mistakes in selection can prove costly. Reflecting on past experiences may provide insights into better decisions. Investing time in understanding these options can ultimately lead to superior performance in aggregate production.

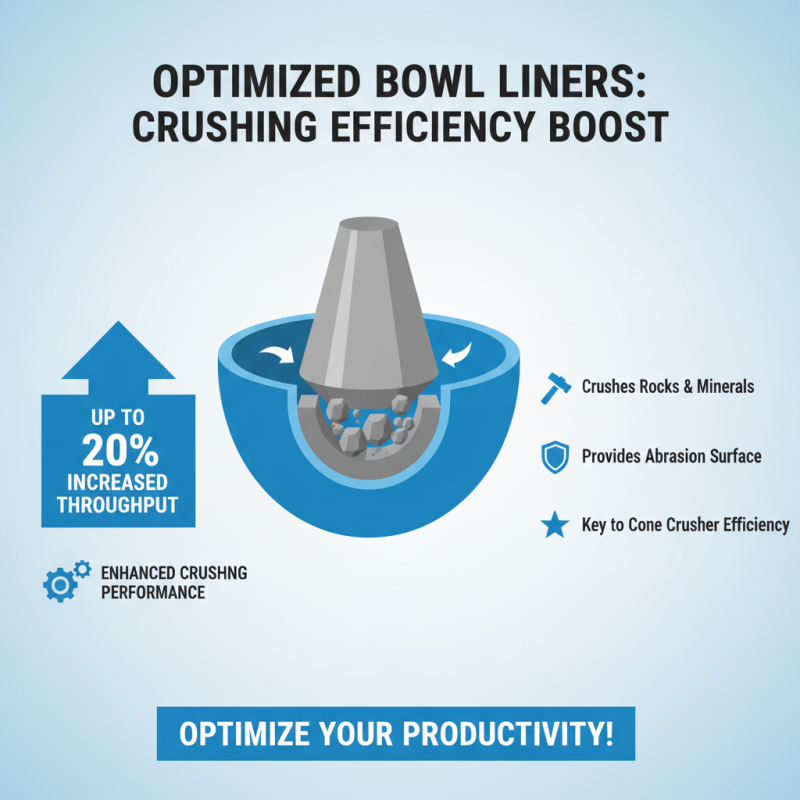

Bowl liners play a vital role in the efficiency of cone crushers. They are responsible for crushing rocks and minerals by providing a surface against which material can break. The right bowl liner can enhance crushing performance significantly. According to industry reports, using optimized bowl liners can improve throughput by as much as 20%.

However, selecting bowl liners demands careful consideration. The correct material composition impacts wear resistance and lifespan. Some materials may wear quickly, leading to decreased productivity. A study noted that improper liner selection could increase costs by 15% due to frequent replacements. Users often overlook the importance of matching liners to specific operational conditions, which can hinder performance.

Regular maintenance is crucial for prolonging the life of bowl liners. Inspections should include checking for wear patterns and uneven surfaces. A report indicated that many operators fail to conduct thorough checks, resulting in reduced efficiency. This gap can lead to downtime and increased operational costs. Understanding these aspects can lead to better decision-making and improved performance in the long run.

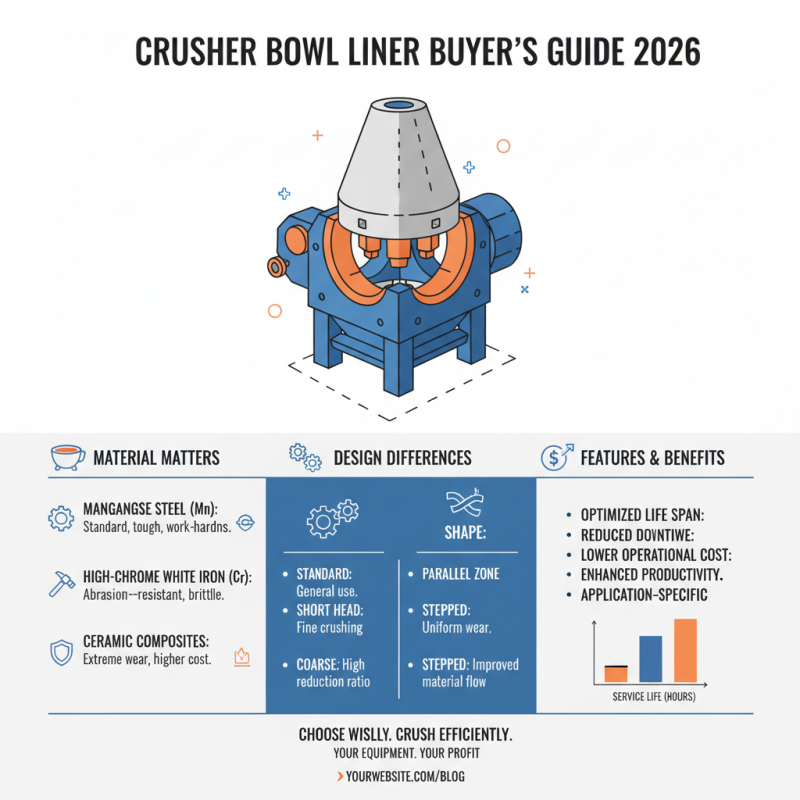

When selecting cone crusher bowl liners, several key features stand out. Material composition plays a pivotal role. High-grade alloys can improve wear resistance. Choosing a liner made from the right material can significantly extend its lifespan. This is essential for efficiency and reduces downtime.

Design is another critical factor. A well-designed bowl liner helps to maintain optimal crushing performance. Consider the profile of the liner. Specific shapes can enhance material flow and reduce uncrushed material. It’s essential to match the design with the application for better results.

Another aspect to reflect on is compatibility. A bowl liner must align well with the crusher model. Mismatches can lead to performance issues. Lastly, think about the cost-effectiveness of your choice. Sometimes, cheaper options may not be the best investment. They can wear out quickly and require more frequent replacements. Keeping these features in mind will guide you toward making a more informed decision.

This chart represents the efficiency ratings of various cone crusher bowl liner materials based on their performance in real-world applications. Higher values indicate better efficiency in maximizing crusher performance.

When selecting bowl liners for cone crushers, the materials used play a crucial role in performance. High-quality materials enhance efficiency and extend the lifespan of the liners. Most commonly, manganese steel is a popular choice. Its exceptional wear resistance and ability to withstand high impacts make it ideal for crushing applications. Manganese levels vary, which can affect durability. Therefore, careful consideration is necessary when choosing the right grade.

Another effective material is chrome-molybdenum steel. This alloy offers improved strength and toughness. It is suitable for high-stress applications where heavy loads are common. However, it may not perform as well in high-abrasion environments. Additionally, ceramic materials are gaining traction for their lightweight and high hardness. They can significantly improve wear resistance but may lack the toughness needed for certain applications.

Manufacturers sometimes overlook the importance of proper lining designs. A well-designed bowl liner can optimize the crushing process. Conversely, a poorly designed liner can lead to imbalances and increased wear. Testing different configurations and materials is essential. Continuous evaluation of performance can reveal opportunities for improvement, ensuring the best efficiency in every crushing operation.

| Material Type | Hardness (HRC) | Weight (kg) | Application | Expected Lifespan (hours) |

|---|---|---|---|---|

| High Manganese Steel | 12-22 | 100 | Standard Crushing | 800-1200 |

| Alloy Steel | 30-40 | 90 | High-Impact Crushing | 600-900 |

| Chrome-Moly Steel | 50-60 | 110 | Secondary Crushing | 1000-1500 |

| Ceramic Coated | 60-70 | 80 | High-Efficiency Crushing | 1500-2000 |

Proper maintenance of cone crusher bowl liners can significantly enhance efficiency and lifespan. Regular inspections are essential. Data from industry reports indicate that preventive maintenance can reduce downtime by up to 30%. Checking for wear and tear is crucial. Bowl liners can wear unevenly under heavy use. This might lead to inefficient crushing and increased costs.

Lubrication is another vital factor. Proper lubrication minimizes friction and heat buildup. Industry studies suggest that improper lubrication can shorten the bowl liner's life by as much as 50%. Using the right type of lubricant is important. Operators should follow specific guidelines to match the lubricant with operational conditions. This ensures optimal performance.

Cleaning and removing debris from the crushing area should not be overlooked. Accumulated materials can cause blockages and overheating. A clean working environment promotes smoother operations. However, many neglect this simple task. Over time, this neglect can lead to costly repairs. Investing time in these maintenance tips will pay off in the long run.

When selecting a cone crusher bowl liner, the options can be overwhelming. Different materials, designs, and features play crucial roles in performance efficiency. A comparative analysis of leading bowl liners for 2026 reveals significant variations. Choosing the right liner affects the lifespan of your equipment and overall operational cost.

One effective tip is to assess the materials used in the liners. High-quality alloys can enhance durability but may come at a higher initial cost. Examine the wear patterns from past experiences. This can inform future purchases and optimize performance. *Consider custom options too,* tailored to specific applications.

Another factor to evaluate is the compatibility with your existing equipment. Not all liners fit all models. An improper fit may lead to early wear or breakage. Keep an eye on installation practices as well. Incorrect installation can negate the benefits of even the best liners. Reflecting on previous choices can guide you toward better decisions.