-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of mineral processing and mining, the efficiency of milling operations is paramount for optimizing productivity and reducing costs. One critical component that significantly influences the performance of both ball mills and SAG mills is the liners. The right choice and maintenance of Ball Mill SAG Mill Liners can lead to enhanced wear resistance, reduced downtime, and improved overall performance of the milling process. This guide aims to decipher the complexities surrounding mill liners, offering valuable insights and practical tips that can empower operators and maintenance teams alike.

Understanding the materials, designs, and installation techniques of Ball Mill SAG Mill Liners is essential for achieving operational excellence. This guide delves into various liner types, their functions, and the impact they have on grinding efficiency and mill longevity. By optimizing liner selection and management strategies, mining operations can not only enhance the milling process but also realize significant cost savings and productivity gains. Join us as we explore the best practices and expert recommendations to ensure your milling operations are performing at their peak.

Ball mills and SAG (Semi-Autogenous Grinding) mills are essential components in the mining and milling industries. Understanding the basics of their liners is crucial for optimizing performance and ensuring longevity. Liners are protective coverings that line the interior of the mills, serving multiple functions such as protecting the mill shell from wear, promoting efficient grinding, and influencing the flow of materials within the mill. The selection and maintenance of liners can significantly impact the overall efficiency and downtime of a milling operation.

Ball mill liners are typically designed to withstand the continuous impact of grinding media and the abrasive nature of the material being processed. They come in various shapes and materials, including rubber and steel, which provide different levels of wear resistance and impact absorption. Choosing the right liner can enhance the grinding efficiency and improve the quality of the output. In the case of SAG mills, the liners not only protect the shell but also aid in the self-grinding process by providing the necessary surface area for efficient particle contact and breakage. Proper understanding of these liners, including their design and function, allows operators to make informed decisions that can lead to improved performance and reduced maintenance costs.

Effective maintenance practices, such as regular inspections and timely replacements, are vital to prolonging the life of both ball and SAG mill liners. Operators should be aware of the signs of wear, including cracks and excessive wear patterns, to avoid unscheduled downtime. By focusing on these foundational aspects of mill liners, teams can enhance their operational efficiency, improve throughput, and ultimately save costs in the long run.

In the realm of mineral processing, the choice of liners in ball mills and SAG mills plays an essential role in enhancing the efficiency and longevity of these critical equipment components. Liners are constructed from various materials, each serving distinct purposes based on the operational conditions. Common liner types include rubber, steel, and composite materials. According to a 2021 study by the International Journal of Mining Science and Technology, rubber liners are favored for their lightweight nature and ability to reduce noise and vibration, significantly improving the working environment. Additionally, the report indicates that rubber liners can reduce grinding energy consumption by up to 5% compared to traditional steel liners.

On the other hand, steel liners are preferred in more demanding applications due to their durability and wear resistance. A report from the Mining Industry Association highlights that steel liners can withstand heavy impacts and are ideal in operations involving harder ores. The compatibility of the liner type to the specific ore characteristics can lead to a reduction in operational costs by improving the efficiency of the grinding process. A comprehensive analysis has shown that the right liner choice can improve mill throughput by as much as 20%, emphasizing the importance of selecting liners that align with the operational requirements of the milling process. Thus, understanding the various liner types and their benefits is crucial for optimizing performance in ball mills and SAG mills.

| Liner Type | Material | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| High Carbon Steel | High Carbon Content | SAG Mills | High wear resistance | Can be brittle |

| Rubber Liners | Natural and Synthetic Rubber | Ball Mills | Noise reduction and improved grinding action | Less durable in high-impact applications |

| Composite Liners | Metal and Rubber | Both Ball and SAG Mills | Combination of durability and flexibility | Cost may be higher |

| Ceramic Liners | High-Alumina Ceramic | Ball Mills | Excellent wear and corrosion resistance | Brittle and more costly |

| Manganese Steel Liners | Manganese Alloy | SAG Mills | High impact resistance | Heavy and can lead to increased wear on grinding media |

The performance of mill liners in Ball Mills and SAG Mills is influenced by a variety of factors that can significantly affect overall grinding efficiency and equipment longevity. One key factor is the material composition of the liners. According to research conducted by the Society for Mining, Metallurgy, and Exploration, the hardness and wear resistance of liner materials can vary substantially, leading to differences in performance. For instance, high-chrome cast iron liners are known for their enhanced wear properties, making them suitable for high-impact applications, whereas rubber liners offer great flexibility and can help reduce noise and vibration.

Another critical factor is the design of the liners themselves. The liner profile, including the shape and arrangement of lifters, plays a vital role in the movement of particles within the mill. A recent study published in the Journal of the Southern African Institute of Mining and Metallurgy found that optimizing the lifter height and angle can lead to a 10-15% increase in energy efficiency. Additionally, proper alignment and installation of the liners are essential to avoid uneven wear and maximize the effective grinding surface area. This emphasizes the importance of a well-planned maintenance program to ensure liners are in optimal condition, ultimately enhancing operational performance and reducing unplanned downtime.

Installing and maintaining mill liners effectively is crucial for optimizing the performance of both ball mills and SAG mills. Proper installation begins with selecting the right type and thickness of liner that matches the specific operational requirements and conditions of the milling environment. Before installation, it's essential to conduct a thorough inspection of the mill to identify any wear or damage. Ensuring that the surfaces are clean and free of debris will facilitate better adherence and alignment of the liners. Utilizing accurate measurement tools to confirm that the liners fit precisely will help to prevent premature wear and improve the efficiency of the milling process.

Regular maintenance of mill liners is vital to extending their lifespan and ensuring efficient operation. This includes implementing a routine inspection schedule to identify signs of wear and tear before they lead to significant problems. Cleaning the liners and surrounding area helps reduce buildup that can lead to misalignment or decreased performance. Additionally, operators should monitor the wear patterns of the liners to make informed decisions regarding when to replace them. Using advanced wear monitoring techniques can provide valuable insights into the best times for maintenance, helping to minimize downtime and maintain optimal production levels.

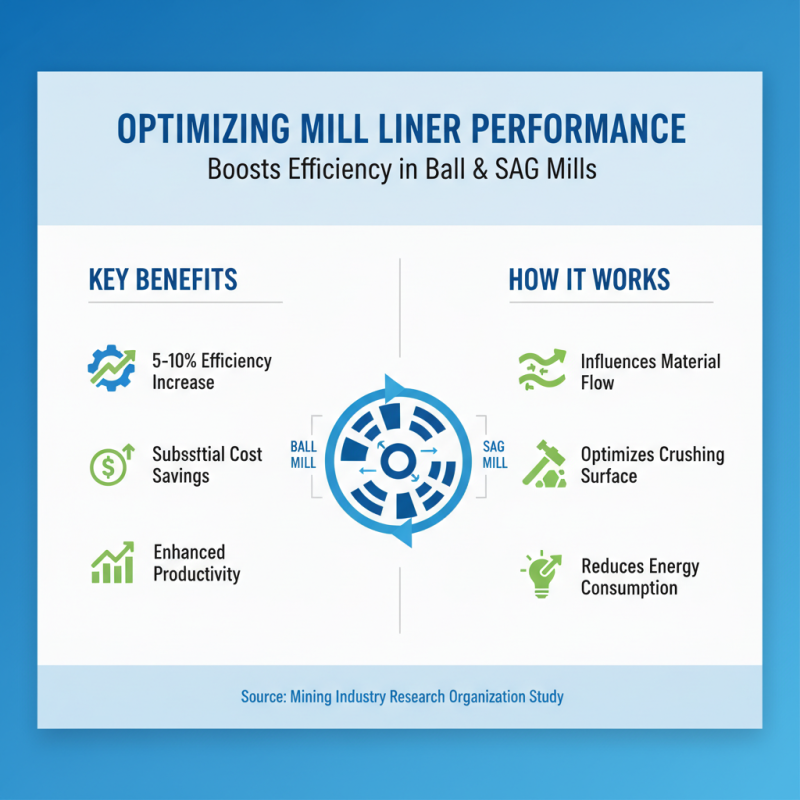

Optimizing mill liner performance is crucial for enhancing the efficiency of both Ball Mills and SAG Mills. Proper liner design can significantly impact the grinding process by influencing the flow of material, the effective crushing surface, and the overall energy consumption. According to a study by the Mining Industry Research Organization, optimizing liner configurations can lead to a 5-10% increase in milling efficiency, which translates to substantial cost savings and productivity gains in mineral processing operations.

To achieve optimal mill liner performance, several factors must be considered. First and foremost is the selection of appropriate materials. High wear-resistant materials such as chrome-molybdenum steel or rubber composites have been shown to extend liner lifespan and reduce replacement frequency, thereby minimizing downtime. Furthermore, the liner's profile and design should be tailored to the specific type of ore being processed. Research from the International Journal of Mineral Processing indicates that customized liner shapes can enhance material flow and grinding efficiency by up to 15%, optimizing the load dynamics within the mill.

Regular monitoring and inspection of the liners are also essential for maintaining performance efficiency. Utilizing advanced technologies, such as wear monitoring systems and 3D scanning, allows for early detection of erosion and wear patterns. This data-driven approach helps in planning timely replacements and adjustments. Effective liner management not only improves the grinding performance but also contributes to a safer operational environment by reducing the risks associated with unexpected liner failures. With these strategies in place, mills can operate at peak efficiency, delivering improved output and reduced operational costs.