-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The efficiency of mining operations significantly hinges on equipment performance. Ball Mill SAG Mill Liners play a pivotal role in this field. According to a recent report by the Mining Industry Association, production losses can reach up to 15% due to equipment downtime. Properly designed liners can reduce these losses.

With rising global demand for minerals, every efficiency gain counts. The right Ball Mill SAG Mill Liners enhance grinding performance and maximize throughput. Studies indicate that optimizing liner materials can increase lifespan by up to 30%. However, improper maintenance can negate these benefits.

Industries often underestimate the impact of liners on overall costs. The initial investment in high-quality liners pays off through improved productivity. Inadequate attention to this aspect might lead to significant financial setbacks. Therefore, understanding the vital role of Ball Mill SAG Mill Liners is essential for achieving optimal mining efficiency.

Ball mills and SAG mills are crucial in mineral processing. Their

liners play a vital role in optimizing performance.

These liners protect the mill shell from wear and improve grinding efficiency, which boosts productivity.

The choice of liner material can greatly impact the milling process. For example,

different materials exhibit varying wear rates. This can lead to changes in processing efficiency over time. If not monitored

closely, this could impact production yield. Regular inspection and replacement of liners can be overlooked due to tight

schedules. This brings potential risks and challenges that should not be ignored.

In the realm of mining, selecting the right liners for ball mills and SAG mills is crucial. Different types of liners impact efficiency and performance significantly. Steel liners are durable and promote higher impacts but can become worn out quickly. Rubber liners, on the other hand, offer excellent noise reduction and less wear on the grinding media. Each type has its own strengths and weaknesses.

Lifters are one key design feature. They create higher ore lifting, leading to better grinding efficiency. However, if they're not designed correctly, they can cause uneven wear patterns. This can affect overall productivity. Wear patterns might indicate that the material isn't optimally processed. Without proper monitoring, these issues can go unnoticed.

Another consideration is the design itself. Flat and wave designs cater to specific needs. Flat liners might provide a smoother flow, but they can increase energy consumption. Wave liners offer better impact but may lead to premature wear. Finding the right balance takes time and reflection. Each operation may require different solutions to ensure that efficiency remains high while managing costs effectively.

The design of liners in ball mills and SAG mills greatly influences grinding efficiency and ore liberation. According to a report by the International Council on Mining and Metals, optimal liner design can improve energy efficiency by up to 30%. This is crucial, as energy costs represent a significant portion of operational expenses in mining.

Liner materials impact wear rates and grinding performance. For instance, rubber liners often provide better wear resistance and noise reduction compared to metallic liners. However, they may sustain lower operational lifespans in some environments. Each miner must assess regional conditions and ore properties before deciding on liner materials.

Tip: Regularly monitor liner wear data. This can help identify when to replace liners, ensuring minimal downtime.

Liner shape also affects ore flow and grinding efficiency. Studies suggest that more complex geometries can enhance fragmentation. Yet, they may complicate installation and maintenance. This balance between performance and practicality often needs reevaluation.

Tip: Evaluate liner effectiveness periodically. Consider both performance metrics and maintenance costs for the best decision.

Choosing the right liner design is not straightforward. Each operation must adapt to its unique challenges. Regular feedback from the grinding process can guide improvements in liner design.

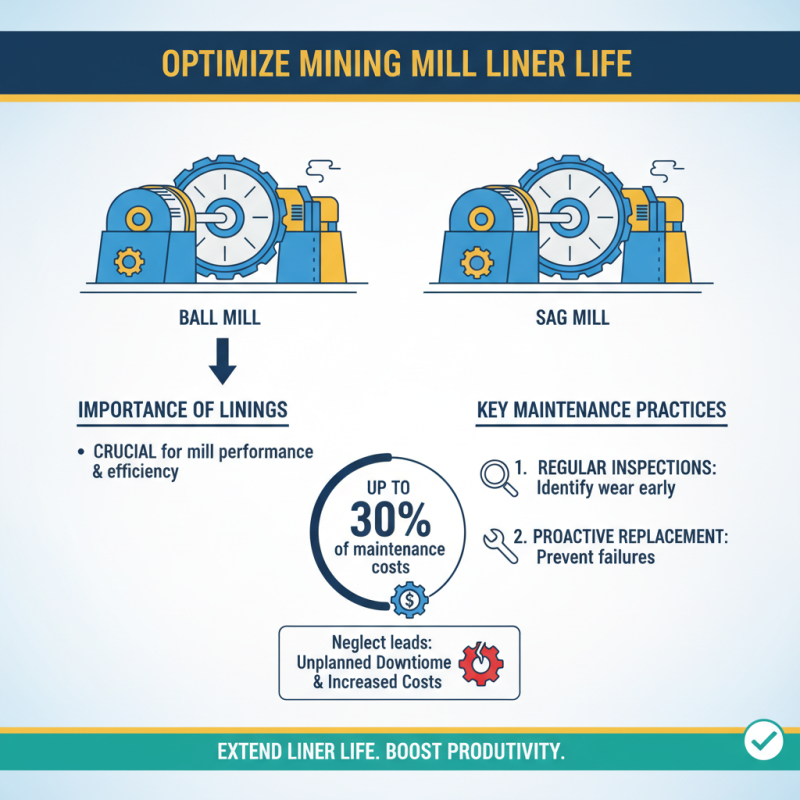

In mining operations, the performance of ball mills and SAG mills heavily relies on the linings used. Effective maintenance practices are crucial for extending the life of these liners. Regular inspections can help identify wear patterns early. For instance, a study indicated that mill liner replacement can account for up to 30% of maintenance costs on mining sites. Neglect can lead to unexpected failures, which disrupt operations and inflate costs.

Another critical aspect is the proper alignment of liners. Misalignment can result in uneven wear and reduced efficiency. According to expert reports, maintaining optimal liner contact can enhance grinding efficiency by about 25%. Utilizing predictive maintenance technologies may also help in anticipating wear trends and scheduling replacements effectively. However, many operations still rely on traditional maintenance schedules. This can lead to costly downtimes when unexpected wear occurs.

It's important to communicate effectively among teams. Issues such as miscommunication can delay maintenance actions. Discrepancies in liner performance data often go unaddressed, leading to lost potential. Field studies indicate a need for better data integration across maintenance teams. Without a clear picture, liner performance and lifespan can suffer significantly. Understanding and improving these practices is essential for achieving greater mining efficiency.

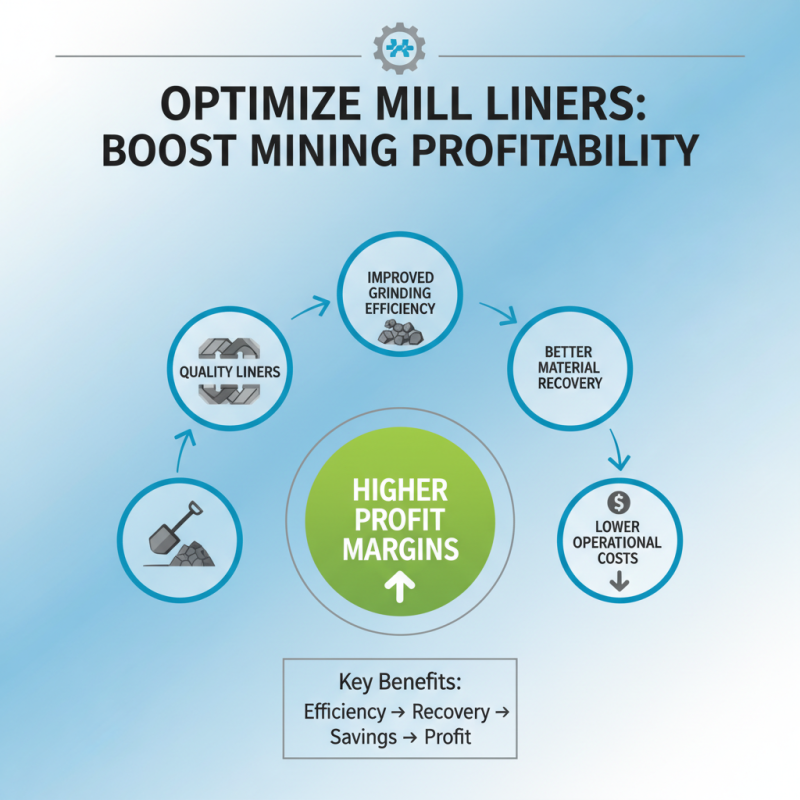

Optimizing mill liners can significantly enhance economic performance in mining operations. By investing in quality liners, mines can improve grinding efficiency. Efficient grinding leads to better material recovery. When you achieve higher recovery rates, operational costs decrease. These savings can boost profit margins.

Choosing the right materials for liners also affects their lifespan. Harder materials resist wear, but they can be costly. Balancing cost and performance is crucial. If liners wear too quickly, replacement costs rise. Frequent downtime for maintenance can disrupt production. This is a risk that operators must manage carefully.

The setup of the mill and liner design can create challenges. Misalignment can cause uneven wear. Understanding the specific needs of different ores is essential. Operators must reflect on their current liner performance regularly. Are they truly maximizing efficiency? Taking the time to analyze changes can reveal opportunities for improvement.