-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the mining industry, understanding the intricacies of Primary Gyratory Crusher Parts is crucial. John Smith, a renowned expert in crusher technology, once stated, "Choosing the right parts can significantly enhance crusher efficiency." This underscores the need for careful selection when it comes to these essential components.

Primary Gyratory Crushers are pivotal in processing large volumes of material. Every part plays a role in ensuring optimal performance and longevity. Maintenance and replacement of these parts are often overlooked, leading to downtime and increased costs. Operators must remain vigilant about wear and tear, as neglect can lead to catastrophic failures.

Navigating the market for Primary Gyratory Crusher Parts can be a daunting task. Not all components are created equal, and some may fail to meet safety and performance standards. Seeking expert advice can help in making informed decisions. Investing time in research can lead to better outcomes. The right parts not only boost productivity but also contribute to the overall safety of operations.

Primary gyratory crushers play a critical role in the mining and aggregate industries. These machines are designed to handle large volumes of material efficiently. The primary function is to reduce the size of rock and ore. They excel in high-capacity applications, processing amounts that smaller crushers cannot manage.

Understanding how these crushers work is essential. They utilize a moving mantle that exerts force against the material. This action crushes the ore, allowing it to pass through. However, there’s complexity in their operation. Maintenance can be challenging, and minor issues might lead to significant downtimes. Operators must regularly inspect the components for wear and tear.

In many cases, the choice of parts can affect performance. High-quality replacement parts may seem like an added cost. But neglecting them can result in inefficiencies. The balance between cost-effectiveness and quality is often a difficult decision. While some may opt for cheaper solutions, the risk of failure is real. Proper training for operators can mitigate many risks. Understanding the equipment is just as vital as understanding the materials processed.

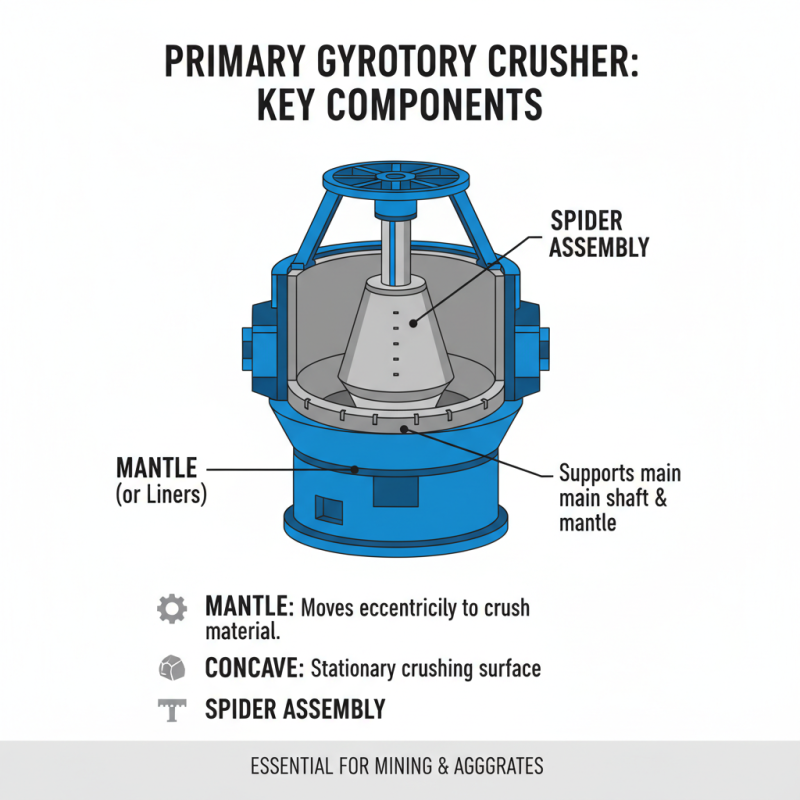

Primary gyratory crushers are essential in mining and aggregate industries. Understanding their key components can enhance the operational efficiency of these machines. The main parts include the mantle, concave, and spider assembly.

The mantle is the rotating part that crushes material against the concave. It's designed to withstand high pressure and heavy wear. Over time, the mantle may wear unevenly, leading to inefficient crushing. Regular inspection is vital to identify wear patterns early. The concave, on the other hand, provides support for the material being crushed. Any damage here can affect the entire crushing process. Keeping it in good shape is crucial for maintaining proper output.

Moreover, the spider assembly holds the main shaft and allows the mantle to rotate smoothly. If the bearings or bolts wear out, it can lead to instability. Noticing vibrations during operation could indicate a deeper issue. Addressing these problems promptly can prevent costly downtime. By understanding and monitoring these components, operators can improve overall performance and extend the life of the gyratory crusher.

Selecting the right materials for gyratory crusher parts is crucial. High-quality materials can enhance durability and performance. Commonly used materials include manganese steel, alloy steels, and other high-strength alloys. These materials resist wear and withstand heavy impact. Manganese steel is specifically known for its high impact strength. This makes it suitable for crushing applications.

However, not all high-strength materials are created equal. Some may fail under specific conditions. It's important to evaluate the operational environment carefully. Consider factors like temperature, humidity, and the type of materials being crushed. This can help in making a more informed choice. Testing proposed materials in real-world applications can also provide valuable insights.

In addition, best practices in maintenance should not be overlooked. Regular inspections and timely replacements can prevent costly downtime. Overlooked components can lead to unexpected failures. It’s a constant learning process. Each experience can teach valuable lessons. Effective material selection is intertwined with operational efficiency. Every choice impacts overall productivity and equipment longevity.

Maintaining a gyratory crusher is crucial for optimizing its lifespan. Regular inspections can prevent unexpected breakdowns. According to industry reports, properly maintained crushers can run up to 30% longer than neglected ones. Operators should prioritize routine checks of wear parts, ensuring they are replaced before they fail.

Tips for maintenance include: keeping the crushing chamber clean. This prevents accumulation of debris that can cause wear. Lubrication is essential; a lack of it can lead to overheating and increased wear rates. Timing the replacement of critical components can save money in the long run.

Another important point is monitoring vibration levels. Excessive vibrations can indicate underlying issues. Using vibration analysis technology can help in early detection. Not all operators invest in these technologies, which is a missed opportunity for many. Consistent attention to these details could significantly enhance performance and reduce downtime.

When selecting replacement parts for primary gyratory crushers, quality assurance is crucial. Not all parts are created equal. Look for materials that can withstand harsh conditions. The right components should reduce wear and tear. They need to fit perfectly, ensuring they function as intended. If parts are not compatible, performance will suffer. This can lead to costly downtime.

Performance metrics play a vital role in making decisions. Pay attention to the expected lifespan of the parts. Test results can indicate how well these components perform under pressure. Always consider customer feedback and industry reviews. This can help gauge reliability. It’s wise to analyze how different materials impact efficiency. Sometimes, higher prices do equate to better quality. However, that’s not always the case. Striking a balance is key.

Replacing parts too frequently can indicate a need for deeper assessment. Chasing the perfect part may lead to frustration. But, embracing an iterative approach can yield better results. Explore options and refine your choices over time. Understand that not every solution will deliver exemplary results. Learning from each experience enhances decision-making for the next replacement. Quality assurance and performance metrics are dynamics that require constant attention.