-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of mining and aggregates, understanding "Cone Crusher Liners" is crucial. Experts like John Smith, a leading authority in crusher technology, emphasize, “The right liner can make all the difference.” His insights reveal the importance of choosing the best cone crusher liners for maximized efficiency.

Cone crusher liners serve as the primary wear component. They directly impact the crushing process and overall production rates. Proper selection ensures reduced downtime and optimal performance. However, many operators still struggle with liner choices. Miscalculations can lead to increased costs and unexpected equipment failure.

Knowing about the latest advancements helps in making informed decisions. Various materials and designs are available, each with its own benefits and drawbacks. Finding the perfect fit requires careful consideration and a bit of trial and error. In this ever-evolving industry, staying updated is essential. What might work well today could be less effective tomorrow.

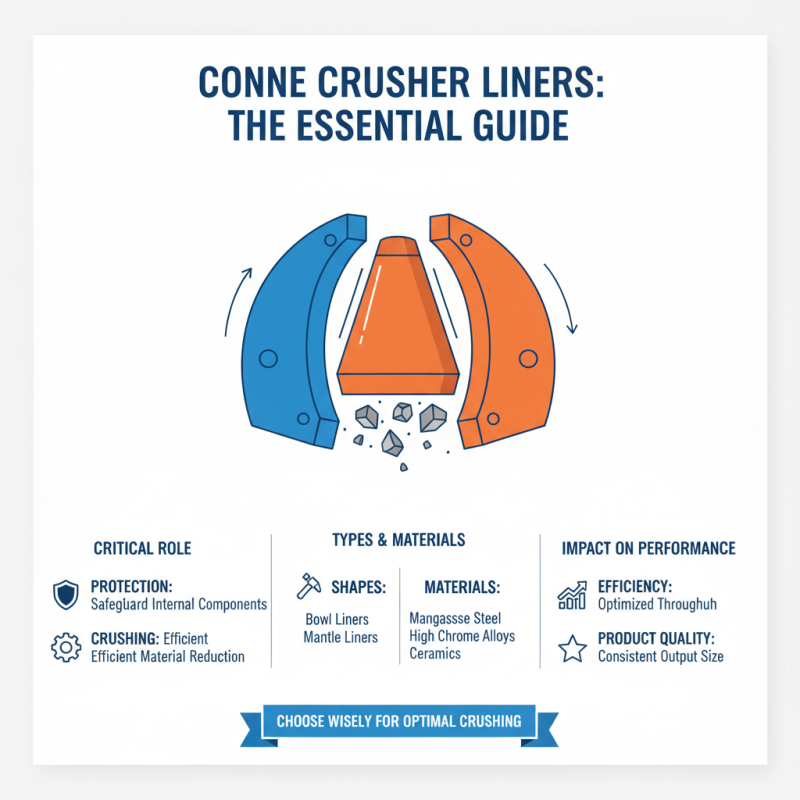

Cone crusher liners play a critical role in the crushing process. They are designed to protect the internal components of the crusher while effectively crushing materials. These liners come in various shapes and materials, tailored for specific applications. The right choice can significantly impact efficiency and product quality.

In crushing operations, liners endure high levels of wear and tear. They must withstand abrasive materials and heavy impacts. This reality means frequent monitoring and timely replacement are essential to avoid costly downtime. A well-maintained liner not only improves performance but also increases the lifespan of the machine itself.

Selecting the appropriate liner material is often challenging. Factors like the material being crushed, throughput, and operating conditions should be considered. Even with the best products, there is always room for improvement and innovation. Reflecting on past performance can lead to better choices in liner design and selection for future operations.

When it comes to manufacturing high-performance cone crusher liners, selecting the right materials is crucial. These liners are pivotal for ensuring efficient crushing and long service life. Commonly, high manganese steel is favored for its remarkable work-hardening properties, making it ideal for handling abrasive materials. However, this choice is not without its challenges. Manganese can be insufficient at higher temperatures, leading to unexpected wear and tear.

Another material often considered is chromium alloy steel. It offers excellent resistance to impact and wear. Yet, balancing its hardness with ductility is tricky. Overly hard liners can become brittle, causing fractures under extreme conditions. Engineers must often experiment with different compositions to find the right balance.

The trend towards using ceramic materials in liners is gaining traction. These can withstand high wear rates and offer significant durability. But they come at a higher cost. Additionally, the installation process can be complicated. These evolving materials reflect an ongoing struggle for manufacturing perfection in the industry. Each choice carries its own set of trade-offs, calling for careful consideration and continuous improvement.

When selecting cone crusher liners, industry standards play a crucial role. Thickness is a key factor. Liners typically range from 1 to 5 inches thick. This variation depends on the specific application and the material being processed. Thicker liners generally offer better wear resistance but may not fit all crushers. It's important to evaluate the operational requirements carefully.

Hardness is another essential property. A hardness level of 12 to 14 on the Mohs scale is common. This ensures durability and longevity in high-impact situations. However, finding the right balance is critical. Liners that are too hard may become brittle. They can crack or chip under heavy loads, leading to unexpected downtimes. Monitoring wear patterns is vital for maintaining effective operations.

Wear resistance is paramount in extending liners’ life. Advanced material compositions can enhance performance. These options, however, come with trade-offs. Choosing a more wear-resistant liner may increase costs. It’s essential to consider both the initial investment and long-term benefits. Assessing the specific needs of your operations is key to making the best choice. Understanding these factors can lead to better decision-making.

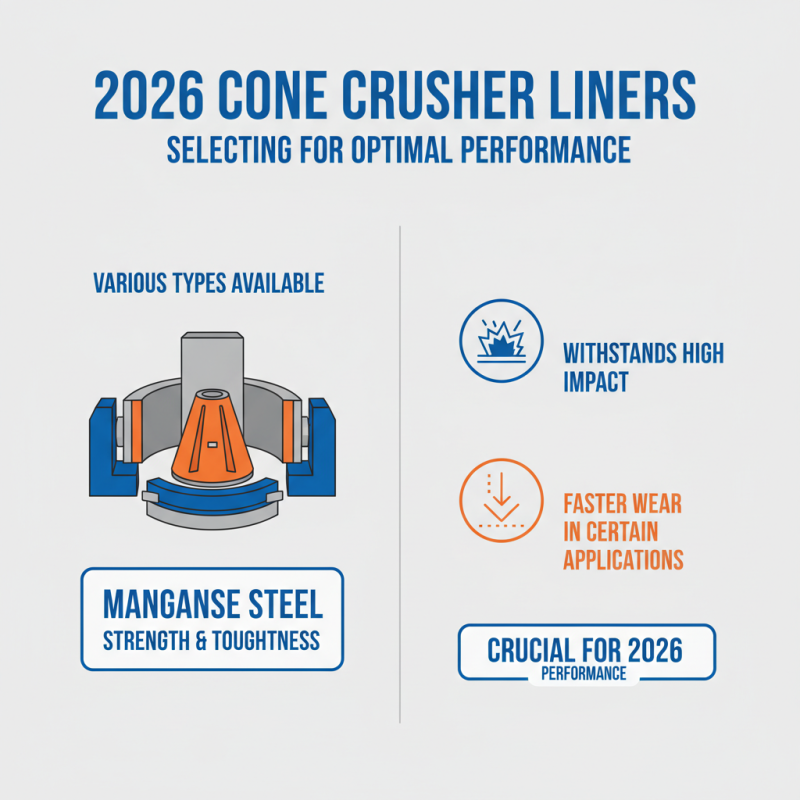

In 2026, selecting the right cone crusher liner is crucial for optimal performance. There are various types available, each with unique characteristics. For instance, manganese steel liners are known for their strength and toughness. They can endure high impact, yet may wear out faster in certain applications.

Another option is high-chrome iron liners, which provide excellent wear resistance. These can be beneficial in abrasive environments. However, they may suffer from brittleness under heavy impact. Choosing the right liner involves weighing these trade-offs carefully. Each type has its advantages and drawbacks.

Some operators mistakenly rely solely on one type of liner without assessing their specific needs. It's important to evaluate factors like material type, crushing conditions, and desired output. Understanding these elements will lead to better decision-making. Quality liners are an investment, but poor choices can lead to costly downtime and repairs. Regular monitoring and adjustments are essential for maximizing the lifespan of the liners.

Maintaining cone crusher liners is essential for optimal performance. Regular inspections help identify wear patterns early. Check for signs of cracking or excessive wear. These issues can lead to decreased efficiency. Addressing them promptly is key to avoiding costly downtime.

Proper lubrication is critical. Consistent lubrication reduces friction. It also helps in preventing premature wear. The oil type and temperature are vital. Ensure they meet the specifications for your equipment. Regular oil changes prevent buildup. This can safeguard your liners and extend their life.

Monitoring production parameters is equally crucial. Track factors like feed size and throughput. Too much feed can overload the system. This increases wear on the liners. Adjust your operations to maintain balance. Reflect on your methods regularly to improve performance. A simple tweak can make a significant difference in lifespan.